- Ana Sayfa

- Transmission Steel

Transmission Steel

Transmission Steel Bars – Cold Drawn Shafting for Power Transmission

Transmission steel—also called transmission shaft steel or drive shaft steel bar—typically refers to round steel bars (e.g. S235JR / St37-2, SAE 1008 / 1010 / 1018) that are cold drawn through one or more dies at room temperature. Cold drawing increases yield and tensile strength, improves tolerances and surface finish, and creates a cost-effective shafting bar suitable for machining, welding and heat treatment.

At HL Metal Demir Çelik Sanayi ve Ticaret Ltd. Şti., we supply transmission steel bars in low- and medium-carbon structural grades as well as alloy steels such as C45 and 42CrMo4, available as as-drawn, peeled / turned and ground finishes with typical h9–h11 tolerances for power transmission, machinery and precision equipment.

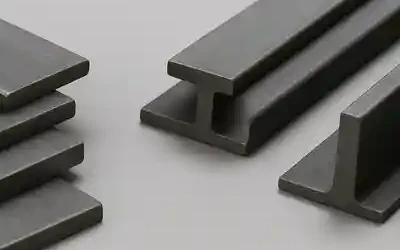

For complementary products, see our steel bars, flat bar & T bar, angle bar and cold rolled steel pipe pages, or explore our steel processing services for cutting, peeling, grinding and heat treatment.

What Is Transmission Steel?

Transmission steel refers to cold drawn steel bars used as transmission shafts, drive shafts and rotating machine components. Bars are drawn at room temperature through one or more dies, rather than being fully heat treated, to create a strong, straight and dimensionally accurate transmission shaft steel.

When improvements are needed mainly by reducing thickness, cold rolling is used and the resulting products are referred to as cold rolled steels. Where ultra-precise surface finish is not required, cold drawn or cold rolled material can often be used as-is. After very high reductions, stress-relief annealing may be needed to reduce residual stresses.

HL Metal supplies transmission steel bar across the full range from standard S235JR / St37-2 and SAE 1008 / 1010 / 1018 to higher-strength C45 and 42CrMo4, responding to the needs of automotive, power transmission, crane manufacturing, reducers and general engineering.

Materials (Grades & Typical Use Cases)

Transmission steels are produced from structural and quenched & tempered grades, supplied as as-drawn, peeled / turned, or ground bars:

Low / Medium-Carbon Structural Grades

- S235JR (St37-2), St44-2, St52-3, SAE 1008 / 1010 / 1018

- High weldability and good machinability

- Cost-effective solution for general shafts, pins and drive components

- Ideal where moderate strength and excellent fabrication properties are required

Higher-Strength / Alloyed Grades

- C45, 42CrMo4, 16MnCr5, 20MnCr5

- For heavier loads, impact and fatigue-prone applications

- Suitable for induction hardening, quenching & tempering (QT) or case hardening

- Used in gears, pinions, cardan shafts, crane shafts and precision spindle parts

Our engineering team can recommend the optimal transmission shaft steel grade based on load spectrum, hardness profile and desired machining strategy.

Sizes & Tolerances (Stock Ranges)

HL Metal offers transmission steel bars in a wide range of diameters, lengths and tolerance classes:

- Diameter: 5–100 mm typical (larger diameters available on request)

- Lengths: 6 m and 12 m standard; custom cut-to-length available

- Tolerances: commonly h9 or h11 (ISO fits), depending on finish (as-drawn / peeled / ground)

For precision ground shafts and bearing seats we can offer tighter fits (e.g. h8 or better) along with roundness and roughness values suitable for seals and bearings.

Manufacturing – Cold Drawing vs Hot Rolling

Cold Drawing (Room Temperature)

- Bars are pulled through dies at approximately 25 °C

- Increases yield and tensile strength vs hot-rolled base material

- Improves straightness and dimensional accuracy (e.g. h9 / h11)

- Provides smoother surface finish and better chip breaking

- Enhances machinability on CNC lathes and machining centers

- Stress-relief annealing may be applied after heavy reductions

Hot Drawing / Hot Rolling (High Temperature)

- Bars are deformed at elevated temperature, typically as hot-rolled base

- Excellent formability for larger diameters and sections

- Efficient tonnage and lower unit cost at scale

- Looser tolerances and rougher surface vs cold drawn condition

- Often followed by peeling / turning or grinding to improve surface and concentricity

- Chosen when tight h9 tolerance is not required or downstream machining is planned

HL Metal can supply both cold drawn transmission steel bars and hot rolled / hot drawn bars prepared for further machining, giving flexibility in cost and performance.

Surface Quality & Tolerance (Finish Options)

The choice of finish for transmission shafting steel depends on required fit, surface quality and machining allowance:

- As-drawn: good accuracy and surface, typical tolerance h9 / h11

- Peeled / Turned: improved surface and concentricity, stable for machining

- Ground / Polished: tightest fits, best roundness and roughness for bearing seats

Hot-rolled or hot-drawn bars can be peeled and ground to reach similar functional surfaces when high-precision transmission components are required.

Key Properties of Transmission Steel Bars

Engineers typically select transmission steel bar based on a combination of mechanical properties, dimensional control and processing capability:

- Round cross-section optimized for rotation and bearing fits

- High weldability, especially for low-carbon grades like S235JR and SAE 1018

- Higher yield and tensile strength than hot-rolled condition thanks to cold work

- CNC-friendly machinability with improved chip control from cold drawing

- Compatibility with induction hardening, carburizing or nitriding (grade-dependent)

- Cost-effective compared with many free-cutting or high-alloy alternatives

Rule of thumb: cold drawing can raise yield ~10–30% and tensile ~5–20% vs hot-rolled condition (exact gains depend on grade, reduction and any post-processing).

Technical Table – Finish vs Typical Attributes

| Finish | Typical Tolerance | Surface | Machinability | Typical Use Case |

|---|---|---|---|---|

| Hot-Rolled / Hot-Drawn | h11–h13 (indicative) | Scaled / rougher | Good (after facing / turning) | Large diameters, cost-sensitive, further machining |

| As-Drawn (Cold) | h9–h11 | Smooth | Very good (chip break) | General shafts, pins, standard bearing fits |

| Peeled / Turned | h9–h11 | Bright | Very good | Improved concentricity, preparation for grinding |

| Ground / Polished | h8–h9 or tighter* | Brightest, fine roughness | Excellent | Precision bearing seats, seal lands, high-speed shafts |

*Tighter tolerances available on request, depending on diameter and grade.

Technical Table – Indicative Grade Selection

| Application Target | Recommended Grades | Heat-Treat Option | Weldability | Surface Hardening |

|---|---|---|---|---|

| General shafts & pins (cost-efficient) | S235JR, SAE 1018 | Stress-relief as needed | Very good | Limited (induction possible on 1018) |

| Heavy-duty shafts | C45, 42CrMo4 | QT or induction hardening | Moderate | Excellent |

| Gears / pinions (case-hardened) | 16MnCr5, 20MnCr5 | Carburizing / nitriding | Good | Outstanding |

| High-speed / precision shafts* | 42CrMo4 (QT), bearing steels* | Ground finish | Moderate | Excellent |

*For very high-speed spindles and special bearings, dedicated bearing steels can be offered on request.

Weight Calculation – Formula & Ready Table

The theoretical weight per meter of transmission steel bars can be calculated using the standard round bar formula:

Formula (per meter):

kg/m = (π × d² / 4) × 7.85 × 10−6

where d is in mm and density ≈ 7.85 g/cm³ (≈ 7850 kg/m³).

The following table shows common diameters with theoretical bar weights; values are rounded and provided for both 6 m and 12 m bar lengths.

| Ø (mm) | kg/m | 6 m (kg) | 12 m (kg) |

|---|---|---|---|

| 5 | 0.154 | 0.925 | 1.850 |

| 6 | 0.222 | 1.332 | 2.663 |

| 8 | 0.395 | 2.368 | 4.735 |

| 10 | 0.617 | 3.699 | 7.398 |

| 12 | 0.888 | 5.327 | 10.654 |

| 14 | 1.208 | 7.248 | 14.496 |

| 16 | 1.578 | 9.468 | 18.936 |

| 18 | 1.998 | 11.988 | 23.977 |

| 20 | 2.466 | 14.796 | 29.592 |

| 22 | 2.984 | 17.904 | 35.809 |

| 25 | 3.848 | 23.091 | 46.182 |

| 28 | 4.835 | 29.010 | 58.020 |

| 30 | 5.551 | 33.307 | 66.614 |

| 32 | 6.317 | 37.902 | 75.804 |

| 35 | 7.510 | 45.059 | 90.119 |

| 36 | 7.992 | 47.953 | 95.906 |

| 38 | 8.984 | 53.905 | 107.811 |

| 40 | 9.866 | 59.198 | 118.396 |

| 45 | 12.489 | 74.933 | 149.866 |

| 50 | 15.414 | 92.484 | 184.969 |

| 55 | 18.640 | 111.839 | 223.677 |

| 60 | 22.195 | 133.173 | 266.346 |

| 65 | 26.064 | 156.383 | 312.766 |

| 70 | 30.246 | 181.478 | 362.957 |

| 75 | 34.741 | 208.446 | 416.892 |

| 80 | 39.458 | 236.750 | 473.501 |

| 90 | 49.940 | 299.637 | 599.275 |

| 100 | 61.654 | 369.923 | 739.845 |

For special diameters, stainless transmission steel or case-hardening grades, we can provide custom transmission bar weight tables upon request.

Applications – Where Transmission Steel Is Used

Automotive & Power Transmission

- Transmission shafts and axles

- Gears, pinions and cam shafts

- Cardan shafts and drive couplings

Industrial Machinery

- Reducer shafts and gearmotor shafts

- Conveyor rollers and crane shafts

- Spindle parts and machine tool components

Construction & General Engineering

- Motion and drive components in hoists and elevators

- Precision pins, locating pins and guide bars

- Custom mechanical linkages and actuators

Precision Equipment

- High-speed motor shafts

- Lab instruments and metering devices

- Measurement and control equipment

Many of these applications also make use of flat bar and T bar or angle bar for brackets, frames and supports, which HL Metal can combine in the same shipment.

Pricing, Export Capabilities & Procurement

Transmission steel bar price is influenced by several factors:

- Diameter and length (kg per bar), grade and finish (as-drawn / peeled / ground)

- Heat treatment (QT, stress-relief, case hardening)

- Testing and certificates (e.g. EN 10204 3.1, additional NDT if required)

- Order volume, cut-to-length plan and lead time

- Market inputs: raw material, energy, freight and FX rates

HL Metal supplies transmission steels and shafting both within Turkey and to international customers across Europe, the Middle East and North Africa. We provide secure bundling, seaworthy packaging and full documentation packages for export deliveries (EXW, FCA, FOB, CFR, CIF, DAP, DDP as required).

As your shafting bar supplier, we can combine transmission steel bars with other long products such as steel bars, flat and T bars and cold rolled pipes into efficient project shipments.

FAQ – Transmission Steel & Shafting Bars

1) What is the difference between cold drawn and hot rolled transmission steel?

Cold drawn transmission steel offers higher strength, tighter tolerances (h9–h11) and a smoother surface than hot rolled bar. Hot rolled / hot drawn bars are more economical and suitable when looser tolerances or additional machining are planned.

2) Which grades are most commonly used for transmission shafts?

For cost-effective general shafts, S235JR and SAE 1018 are common. For heavy-duty shafts, C45 and 42CrMo4 are preferred; for case-hardened gears and pinions, 16MnCr5 and 20MnCr5 are widely used.

3) Can transmission steel bars be supplied peeled and ground?

Yes. HL Metal delivers peeled / turned and ground transmission bars with tight concentricity, roundness and surface roughness suitable for bearing seats and seal lands.

4) Do you provide EN 10204 3.1 certification?

Absolutely. Our transmission steel bars are supplied with EN 10204 3.1 mill test certificates and additional testing (UT, hardness, microstructure) can be arranged on request.

5) Can HL Metal help with grade selection and machining strategy?

Yes. Our team provides application engineering support to help you choose the optimal transmission shaft steel grade, finish and heat treatment route, aligning performance, machinability and cost.

Get Availability & Best Transmission Steel Bar Price

HL Metal Iron & Steel is your trusted partner for transmission steels and shafting—backed by application engineering, EN 10204 3.1 certification, guaranteed h9–h11 tolerances and expedited logistics. We supply both stock and custom runs in S235JR, SAE 1018, C45 and 42CrMo4 across Ø5–100 mm, handling cutting, peeling / turning, grinding, heat treatment and quality control under one roof.

📧 Send Your Transmission Steel Specification & Get a Fast Quote

Kindly send your specifications (diameter range, grades, finish, length and annual volume); we will revert with a competitive offer and an optimized cutting and logistics plan. For project packages we can also include flat bar and T bar, steel bars and angle bars in one consolidated shipment.

Contact HL Metal – Ask for Transmission Steel QuotePlain Carbon Steels (Manufacturing Steels): Definition & Scope

Plain carbon steels—also called unalloyed machine-building steels or manufacturing steels—are non-alloy steels with approximately 0.20–0.60% C. As carbon increases, hardenability and attainable surface hardness rise, while toughness and weldability generally decrease. For thicker sections or where higher through-hardening is required, low-alloy steels are typically preferred.

Metallurgy & Key Properties

Plain carbon steels provide moderate strength, predictable behavior in surface hardening, and a cost-efficient balance of properties for general mechanical parts.

Hardenability vs. carbon: Higher carbon improves response to quench/induction hardening; however, thick sections may not fully harden through the core.

Strength–toughness trade-off: Strength and hardness increase with carbon, while toughness and ductilitydecline.

Microstructure control: Through hot rolling, normalizing, quenching and tempering, or surface hardening, the matrix (ferrite/pearlite/martensite) is tuned to need.

Processing Routes

Cold Drawing (Room-Temperature Deformation)

Bars are pulled through dies to refine dimensions, straightness, and surface finish while raising yield and tensile strength without a full hardening cycle. After heavy reductions, stress-relief may be applied.

Cold Rolling (Thickness Reduction)

Used primarily for sheet/strip where property improvement is achieved by thickness reduction; products are referred to as cold-rolled steels.

Surface Hardening Options

Carburizing (≤0.25% C): Builds a hard, wear-resistant case over a tough core—common for gears, pins, and wear surfaces.

Flame/Induction hardening (≥0.40% C): Directly hardens the surface of medium-carbon grades (e.g., C45) for high wear resistance with retained core toughness.

Machinability & Weldability

Machinability: Lower than low-carbon steels but acceptable; resulfurized variants enhance chip control and tool life.

Weldability: Declines with carbon content. Use preheat/interpass control and proper procedures on medium-carbon grades to avoid HAZ cracking and preserve toughness.

Applications

Designed for machine elements not requiring high alloy strength, including shafts, pins, gears and gear components, bolts, axles, hooks, mold sets, and general hardware in vehicle, engine, machine, and equipmentmanufacturing. The machine-building sector relies heavily on these steels for robust, economical parts.

Grades & Designations (Examples)

Common descriptors include SAE 1030/1040/1050/1060 and their European counterparts C30/C40/C50/C60. Resulfurized versions (e.g., C30R/C40R/C50R/C60R) improve machinability; typical S content is 0.020–0.035%.

When to Choose Low-Alloy Alternatives

If your design demands higher hardenability, deeper case depth on thick sections, elevated toughness, or better strength-to-weight, step up to low-alloy grades (e.g., Cr-Mo, Ni-Cr-Mo systems) with appropriate heat treatment.

Plain Round Steel Bars (Smooth Round) — Advanced Overview

Plain round steel bars—often called smooth round bars or simply rounds—are the most common long-product form for manufacturing steels. They are the workhorse input for rotational and load-bearing components where consistency, finish, and dimensional control directly impact performance.

What They Are

Cylindrical bars supplied as hot-rolled, cold-drawn (bright), peeled/turned, or ground products. The chosen route affects tolerance class (e.g., h9/h11), straightness, roundness, and surface roughness—and ultimately bearing life, seal wear, and assembly precision.

Production Routes & Finishes

Hot-Rolled Rounds: Economical for larger diameters and rough machining. Scale present; tolerances are looser but suitable where parts will be turned/grinded later.

Cold-Drawn (Bright) Rounds: Enhanced strength, straightness, and surface quality with tighter h9/h11tolerances—ideal for general shafts and precision fit components.

Peeled/Turned Rounds: Scale removed and diameter trued; an excellent pre-grind condition with stable machinability.

Ground/Polished Rounds: Tightest tolerances and lowest roughness for bearing journals, seal lands, and high-speed shafts.

Typical Sizes & Tolerances (Indicative)

Diameters: Commonly Ø5–Ø100 mm (larger on request).

Lengths: 6 m and 12 m standard; cut-to-length service reduces scrap and setup time.

Tolerances: h11 for general purpose; h9 (or tighter if ground) for bearing fits and precision assemblies.

Performance Advantages

Dimensional stability & straightness reduce vibration, misalignment, and premature bearing wear.

Improved surface integrity enhances fatigue resistance and running accuracy.

Lower total machining time with bright/peeled/ground stock; better chip control on cold-drawn material.

Predictable case-hardening and induction response on suitable carbon levels (e.g., C30–C60, C45).

Where They’re Used

Power transmission: drive and intermediate shafts, pins, spindles, hubs.

General mechanical: gears/gear hubs (with case hardening), couplings, threaded fasteners, bush carriers.

Automotive & industrial equipment: axles, steering/column parts, conveyor and crane shafts, fixtures and tooling.

Ordering Checklist (What to Specify)

Grade & condition: SAE 1030/1040/1050/1060, C30/C40/C50/C60; resulfurized “R” options if machinability is critical.

Diameter, length & tolerance class: h11 for general; h9 or ground for precision fits.

Finish: hot-rolled, cold-drawn (bright), peeled/turned, ground/polished.

Heat treatment/surface hardening: as-rolled/normalized, Q&T, carburized, or induction hardened.

Quality documentation: request EN 10204 3.1 MTC, straightness/roundness criteria, and any additional NDT requirements.

Practical Selection Notes

Use carburizing on low-carbon rounds (<0.25% C) when you need a hard, wear-resistant case with a tough core (e.g., small gears, pins).

Choose flame/induction hardening on medium-carbon rounds (≈0.40–0.55% C, e.g., C45/C50) for localized surface hardness with minimal distortion.

For thick sections or high duty cycles, consider low-alloy rounds to achieve deeper hardening and better fatigue toughness.