- Ana Sayfa

- Teardrop Patterned Sheet

Teardrop Patterned Sheet

Teardrop Patterned Sheet – Anti-Slip Chequered & Tread Plates

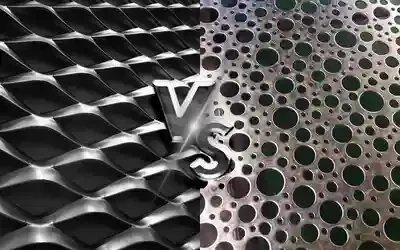

Teardrop patterned sheet (also known as tear drop patterned sheet, chequered plate, checkered plate, tread plate or floor plate) is a hot-rolled steel sheet with an embossed pattern designed to provide anti-slip performance and higher surface grip. These products are widely used as anti-slip steel plates and industrial floor plates in heavy-duty environments.

By embossing raised teardrop or batten patterns onto the surface of hot-rolled sheets, the material combines mechanical strength, impact resistance and slip resistance in a single product. HL Metal supplies teardrop patterned sheets and tread plates in a wide thickness range from 1.50 mm to 16.00 mm and widths between 1000 mm and 1500 mm, tailored to ramps, platforms, machinery bases, truck beds and architectural applications.

- What Is Teardrop Patterned Sheet?

- Teardrop Patterned Sheet Dimensions & Weight Chart

- Teardrop Patterned Sheet Production Process

- Advantages of Teardrop / Chequered Plate

- Common Applications – Industrial & Architectural

- Material Grades & Standards

- Cutting, Welding & Surface Processing

- Export, Packaging & Logistics

- Teardrop Patterned Sheet from HL Metal

What Is Teardrop Patterned Sheet?

Teardrop patterned sheets are produced by embossing special patterns onto the surface of hot-rolled steel sheets. The raised teardrop (tear drop) or batten pattern increases friction and provides a non-slip surface even in wet, oily or inclined conditions. This makes them ideal as anti-slip floor plates, industrial stair treads, platform plates and walkways.

Compared to flat plate, teardrop plate and chequered plate offer:

- Higher slip resistance under foot traffic and wheeled loads.

- Improved impact and bending resistance due to the embossed pattern geometry.

- Enhanced visual safety in industrial and public areas.

- Attractive textured appearance for decorative exterior cladding and architectural details.

Teardrop Patterned Sheet Dimensions & Weight Chart

HL Metal supplies teardrop patterned sheets in standard stock sizes with different “nominal / base” thickness and raised pattern combinations (e.g. 2/3 mm, 3/4 mm). The following table shows typical teardrop patterned sheet dimensions and weights for common sizes:

| Nominal Thickness (mm) | Dimensions (mm) | Weight per Sheet (kg) |

|---|---|---|

| 2/3 mm | 1000 × 2000 mm | 42.00 kg |

| 2/3 mm | 1250 × 2500 mm | 63.00 kg |

| 2/3 mm | 1500 × 3000 mm | 90.00 kg |

| 3/4 mm | 1000 × 2000 mm | 54.00 kg |

| 3/4 mm | 1250 × 2500 mm | 87.00 kg |

| 3/4 mm | 1500 × 3000 mm | 126.00 kg |

| 4/5 mm | 1000 × 2000 mm | 68.00 kg |

| 4/5 mm | 1250 × 2500 mm | 113.00 kg |

| 4/5 mm | 1500 × 3000 mm | 162.00 kg |

| 5/6 mm | 1000 × 2000 mm | 87.00 kg |

| 5/6 mm | 1250 × 2500 mm | 138.00 kg |

| 5/6 mm | 1500 × 3000 mm | 198.00 kg |

The first value in the thickness (e.g. 2/3 mm) typically represents the base plate thickness, while the second value includes the raised teardrop pattern. For other thicknesses, widths and lengths up to 16 mm and 1500 mm width, please contact HL Metal. You can also use our online steel weight calculator for project-specific weight calculations.

Teardrop Patterned Sheet Production Process

The teardrop patterned sheet production process involves several key steps to guarantee mechanical performance and consistent pattern quality:

1. Raw Material Selection

Typically, carbon steel grades such as S235JR, S275JR or S355JR are used for teardrop patterned steel sheets. For specific environments, stainless steel or other alloyed steels can also be used on request. Raw material selection considers yield strength, weldability and corrosion protection needs.

2. Hot Rolling

Steel billets or slabs are hot-rolled into flat sheet or plate with the target base thickness. This stage defines the core mechanical properties of the floor plate, ensuring adequate load-bearing capacity for industrial floors, ramps and heavy traffic areas.

3. Pattern Embossing

Flat hot-rolled sheets are then passed through patterned rollers that emboss the teardrop texture onto the surface. The raised pattern geometry provides the characteristic appearance and anti-slip properties associated with chequered plate / tread plates.

4. Heat Treatment & Surface Processing (If Required)

Depending on the application, additional heat treatment may be performed to fine-tune mechanical properties. Optional surface processing such as shot blasting, priming or galvanizing can be applied to improve corrosion resistance and paint adhesion.

5. Cutting & Sizing

Finally, teardrop patterned sheets are cut to specified dimensions and prepared for delivery. HL Metal can supply standard stock sizes or custom cut-to-size tread plates according to drawing and nesting requirements.

Advantages of Teardrop / Chequered Plate

Teardrop patterned sheets and chequered plates offer several advantages over plain flat plates:

- Anti-slip performance: the raised teardrop / diamond pattern significantly improves grip, reducing the risk of slipping on stairs, ramps and platforms.

- Higher stiffness & strength: the embossed pattern increases local rigidity, enabling lighter plates to carry similar loads compared to plain plate in some designs.

- Durability: produced from structural carbon steel plate, teardrop sheets resist impact and heavy rolling loads in industrial zones and transport vehicles.

- Easy fabrication: teardrop plate can be cut, drilled, welded and bolted using standard steel fabrication processes.

- Cost-effective safety solution: compared to complex surface coatings, anti-slip steel plate provides a mechanical, long-term grip solution with low maintenance.

Common Applications – Industrial & Architectural

Thanks to their anti-slip, durable and aesthetic properties, teardrop patterned sheets are widely used in:

- Ramps and loading docks – vehicle and pedestrian ramps, loading areas and access ramps.

- Machinery bases & heavy industrial zones – machine platforms, base plates, maintenance areas.

- Walkways & platforms – catwalks, service platforms, industrial walkways, mezzanines.

- Fire escapes & stair treads – steps and landings requiring safe footing.

- Warehouse floors & working platforms – anti-slip surfaces for forklifts and pallet trucks.

- Truck and trailer beds – floor plates for commercial vehicles, tippers, lowbeds and trailers.

- Decorative exterior cladding – façade elements, protective barriers and design features.

- Shipbuilding and offshore – decks, gangways and working platforms in shipyards and marine structures.

- Wet floor areas – industrial washing zones, process areas and outdoor stairs exposed to rain and snow.

Material Grades & Standards

HL Metal typically supplies teardrop patterned sheets manufactured from structural hot rolled steel plate according to EN standards, such as:

- S235JR – general structural steel plate for standard flooring and platforms.

- S275JR – medium strength structural plate for higher load levels.

- S355JR – high strength plate for heavy-duty industrial floors and structural applications.

On request, teardrop / chequered plates can be supplied with:

- EN 10204 3.1 mill test certificates.

- Alternative standards (ASTM, BS, GOST) corresponding to the required project specification.

- Additional requirements for impact toughness, flatness or dimensional tolerances.

Cutting, Welding & Surface Processing

As a steel service centre, HL Metal can deliver not only standard stock sheets but also processed teardrop patterned plates according to customer drawings:

- Plasma cutting / oxy-fuel cutting of chequered plate contours, openings and customised shapes.

- Drilling, countersinking and edge preparation for bolted connections and welded assemblies.

- Shot blasting & shop primer coating for improved corrosion protection and paint adhesion.

- Optional galvanizing for outdoor and aggressive environments.

Export, Packaging & Logistics

HL Metal is experienced in exporting teardrop patterned sheets, chequered plates and tread plates to international markets. To guarantee safe and efficient deliveries, we focus on:

- Secure packaging: strapped bundles, wooden supports and edge protection to prevent damage.

- Moisture protection: optional wrapping and rust protection for sea shipments.

- Optimised loading plans: combining plates with other steel products to maximise container or truck utilisation.

- Flexible Incoterms: EXW, FCA, FOB, CFR and other terms according to customer preference.

Teardrop Patterned Sheet from HL Metal

Whether you are looking for teardrop patterned sheets, chequered plates, tread plates or floor plates for local projects or export, HL Metal Demir Çelik Sanayi offers:

- A wide stock range of standard sizes and thickness combinations (2/3 mm to 5/6 mm and beyond).

- Custom cut-to-size solutions and processed parts ready for installation.

- Competitive pricing and transparent teardrop plate price per ton for project and wholesale orders.

- Technical support in selecting the right plate thickness and grade for your load and safety requirements.

Request Your Teardrop Patterned Sheet & Chequered Plate Offer

Share your required dimensions, thickness (e.g. 2/3 mm, 3/4 mm, 4/5 mm, 5/6 mm), material grade (S235JR / S275JR / S355JR), quantity and delivery terms. Our export team will prepare a detailed quotation including technical data, prices, lead time and loading plan.

Value-Added Processing & Surface Protection for Hot Rolled Steel

Turn your hot rolled steel sheets and plates into finished, ready-to-assemble components. HL Metal combines advanced cutting, forming and protective coating services to support your fabrication process from raw material to final part.

CNC Laser Cutting

Achieve clean edges, tight tolerances and complex geometries with our CNC laser cutting service. From thin-gauge sheet metal to structural plate, our high-performance laser systems deliver precision parts with minimal burrs and reduced finishing work.

CNC Plasma Cutting

For thicker plates and heavy-duty sections, our CNC plasma cutting provides robust and economical cutting performance. Ideal for structural fabrication, machinery frames and industrial steelwork where productivity and reliability are key.

Laser Cutting for Tube & Hollow Section

Customise circular, square and rectangular hollow sections with high-precision laser cutting. We produce slots, holes, mitre cuts and complex contours directly on tubes and hollow sections, reducing welding time and simplifying assembly for structural and architectural projects.

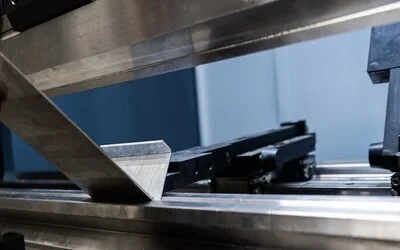

Press Brake Bending

Transform flat hot rolled steel sheets into channels, brackets and complex profiles with our CNC press brake bending. High-tonnage, multi-axis machines ensure consistent angles, repeatable bends and accurate parts ready for welding or bolting.

Sandblasting, Coating & Shop Primer

Prepare your steel surfaces for long-term performance with professional sandblasting, coating and shop primer application. We remove mill scale and rust, create a controlled surface profile and apply shop primer systems that protect your plates and profiles during fabrication, transport and installation.

Galvanizing & Corrosion Protection

Extend the service life of your hot rolled steel in outdoor and aggressive environments with our galvanizing solutions. Hot-dip zinc coatings provide long-term corrosion protection for structural members, plates and fabricated assemblies.

Discuss Your Project with HL Metal

Need a combined package of hot rolled steel sheet and plate with cutting, bending, blasting, coating or galvanizing? Share your drawings, material grades and delivery terms — our team will prepare a tailored proposal for your project.

Where Are Teardrop Patterned Sheets Used?

Our company closely follows developments in the steel industry and works in full coordination with its entire team. As a forward-thinking, dynamic, and punctual company, we incorporate the latest technologies into our production processes and offer professional-grade patterned sheets of various types.

Just like our other sheet metal models, we manufacture teardrop patterned sheets in custom sizes according to your project needs. Our teardrop patterned sheets are prepared to be durable, non-slip, and ready for use. Thanks to their surface structure and material strength, chequered and other patterned sheets eliminate the risk of slipping.

HL Metal Demir Çelik Sanayi sets itself apart among sheet metal suppliers with its commitment to quality, delivering the teardrop patterned sheet you require on your schedule.

Teardrop Patterned Sheet Supplier - HL Metal Demir Çelik Sanayi

With our experienced and well-equipped team, HL Metal Demir Çelik Sanayi meticulously carries out every stage of its operations to meet all customer requirements flawlessly. All of our products are manufactured in accordance with quality standards.

Our company offers both ST37 grade and stainless 304 grade patterned sheets and also supplies a wide range of other patterned sheet types.

👉 Click here for Teardrop Patterned Sheet Weight Calculation.

With years of experience in the production and supply of teardrop patterned sheets, HL Metal Demir Çelik Sanayi is a reliable choice for your projects. Our support extends beyond the point of sale – we build long-term partnerships with our clients. For us, each sale is not a one-time transaction, but a step toward lasting collaboration.

As HL Metal Demir Çelik Sanayi, we continue to operate precisely and efficiently, driven by a commitment to fully satisfy our customers. In addition to supplying various quality options in patterned sheets, we also operate as a teardrop patterned sheet manufacturer.

With HL Metal, you gain access to durable and high-quality teardrop patterned steel sheets. Our expanding product range is designed to meet all your needs, and we consistently prioritize customer satisfaction through careful and responsive service.

HL Metal Demir Çelik Sanayi offers teardrop patterned sheet and teardrop steel sheet products designed for durability and slip resistance. Our non-slip steel flooring solutions are ideal for industrial platforms, stairs, walkways, and decorative uses. With high-strength patterned steel and anti-slip metal sheet options, we ensure long-lasting performance even under heavy loads. The HL Metal Demir Çelik teardrop sheet and teardrop metal plate provide both functionality and aesthetic appeal. Choose our durable steel patterned sheet products for reliable, safe, and efficient metal flooring applications.