- Ana Sayfa

- Steel Sheets

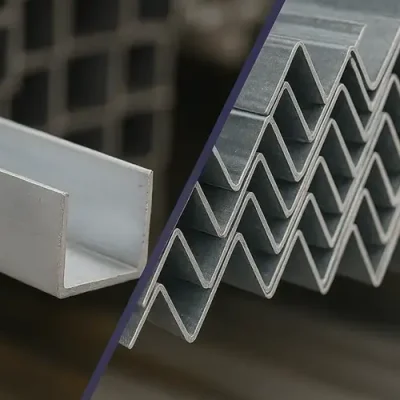

Steel Sheets

Yes, we do. We offer custom-cut sheet metal parts according to your specifications, using advanced technologies such as laser cutting, plasma cutting, and CNC punching to ensure high precision and quality.

Yes, all of our sheet metal products are fully compliant with international standards such as ISO, EN, and ASTM. Material certificates and technical documentation can be provided upon request.

Yes, sheet metal can be galvanized or coated based on your requirements. We offer hot-dip galvanizing, electro-galvanizing, powder coating, and industrial painting to enhance corrosion resistance and surface finish.

Yes, we provide precision bending and forming services for sheet metal using CNC press brakes and rolling machines. Our capabilities allow us to meet a wide range of dimensional and design requirements.

Yes, we export our sheet metal products to various international markets, including Europe, the Middle East, and North Africa. We provide full logistics support and all necessary export documentation to ensure smooth and timely deliveries.

Question and Answer

Frequently Asked Questions About Sheet Metal Products Steel Sheets

Should you require further details regarding our products, please feel free to get in touch with us.

Steel Sheets

Steel sheets are indispensable materials in construction, automotive, manufacturing, and various industrial sectors. Their versatility, durability, and cost-effectiveness make them essential for numerous applications. This guide offers a detailed exploration of the main types of steel sheets, their properties, applications, and why selecting the right type is crucial for project success.

1. Hot Rolled Steel Sheets

Hot rolled steel sheets are produced by rolling steel at high temperatures, typically over 1,700°F (926°C), which is above the recrystallization temperature of steel. This process makes the steel easier to form and results in products with a rough surface finish and slightly rounded edges.

Advantages:

Cost-effective

Suitable for applications where precise shapes and tolerances are not critical

High strength and durability

Applications:

Construction (beams, columns)

Agricultural equipment

Railway tracks

Truck frames

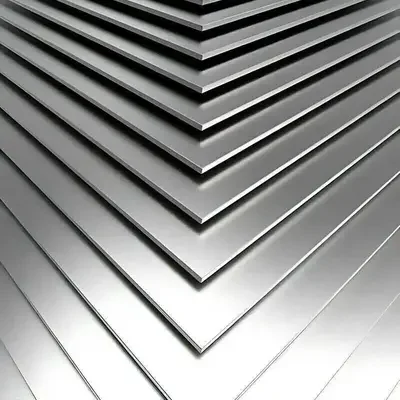

2. Cold Rolled Steel Sheets

Cold rolled steel sheets are processed further from hot rolled sheets by cooling and rolling at room temperature. This improves surface finish and dimensional precision.

Advantages:

Smooth surface finish

Precise dimensions and tighter tolerances

Enhanced mechanical properties (hardness, strength)

Applications:

Automotive body panels

Home appliances

Furniture

Precision tubing

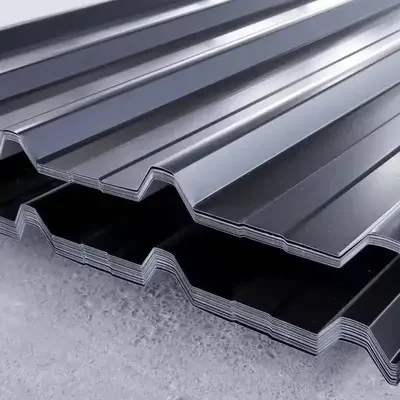

3. Galvanized Steel Sheets

Galvanized steel sheets are coated with a layer of zinc to protect against corrosion. The galvanization process can involve hot-dip galvanizing or electro-galvanizing.

Advantages:

Excellent corrosion resistance

Extended lifespan

Suitable for outdoor and marine applications

Applications:

Roofing and siding

HVAC ducts

Fencing

Automotive components

4. Pre-painted Steel Sheets

Also known as color-coated or coated metal sheets, these are galvanized steel sheets coated with paint, PVC, or other materials to enhance appearance and corrosion resistance.

Advantages:

Aesthetic appeal with various color options

Additional layer of corrosion protection

Ready-to-use for decorative purposes

Applications:

Architectural facades

Roofing and cladding

Household appliances

Interior design elements

5. Stainless Steel Sheets

Stainless steel sheets are alloyed with chromium, offering excellent corrosion resistance and aesthetic appeal.

Advantages:

Outstanding corrosion and heat resistance

Long-lasting, low maintenance

Hygienic surface, ideal for food and medical applications

Applications:

Food processing equipment

Medical devices

Kitchen appliances

Chemical storage tanks

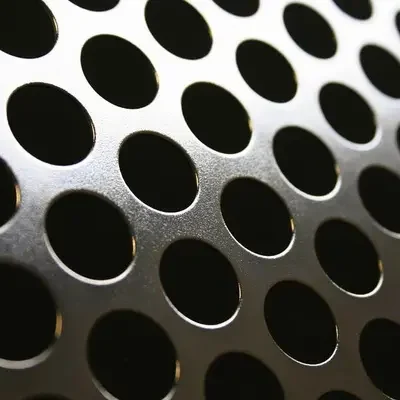

6. Checker Plates (Chequered Sheets)

These metal sheets feature raised patterns (such as diamond or teardrop) to enhance grip and reduce slip.

Advantages:

Non-slip surface

Enhanced mechanical strength

Durable under heavy loads

Applications:

Industrial flooring

Stair treads

Loading ramps

Vehicle flooring

Why Selecting the Right Steel Sheet Matters

Choosing the right type of steel sheet is crucial for ensuring structural integrity, cost-efficiency, and long-term performance. Factors to consider include:

Corrosion Resistance: Will the material be exposed to moisture or chemicals?

Strength Requirements: What loads or stresses will the material endure?

Surface Finish: Is aesthetic appeal or smoothness important?

Formability: Does the application require bending, stamping, or shaping?

Manufacturing Standards

Steel sheets are produced under rigorous standards to guarantee performance:

ASTM (American Society for Testing and Materials)

EN (European Norms)

JIS (Japanese Industrial Standards)

ISO (International Organization for Standardization)

Final Thoughts

Steel sheets are the backbone of countless industries, providing unmatched versatility and performance. Understanding the differences between hot rolled, cold rolled, galvanized, pre-painted, stainless, and checker plates ensures that you choose the best material for your application. Partnering with a trusted steel sheet supplier guarantees access to high-quality products, competitive pricing, and expert guidance, ensuring the success of your next project.

Metal Sheets and Steel Service Centers

Metal sheets are essential materials used across construction, automotive, manufacturing, and infrastructure industries. Steel service centers play a key role in processing, customizing, and distributing these materials, meeting the unique requirements of each project. Understanding the connection between metal sheets and steel service centers is crucial for businesses seeking efficiency, precision, and a competitive edge.

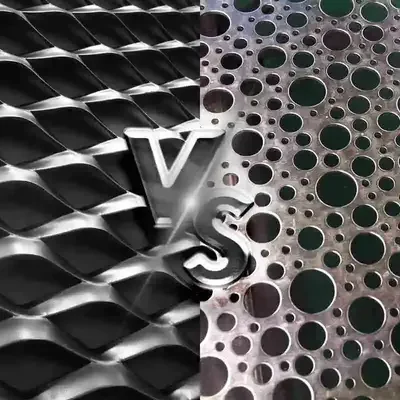

What Are Metal Sheets?

Metal sheets are flat-rolled products made from carbon steel, stainless steel, or alloy steel. They come in various types, including hot rolled sheets, cold rolled sheets, galvanized sheets, pre-painted sheets, stainless sheets, and checker plates. Each offers specific advantages:

Hot Rolled Sheets: Cost-effective and strong, ideal for structural work.

Cold Rolled Sheets: Smooth finish and tight tolerances, used in automotive and appliance industries.

Galvanized Sheets: Zinc-coated for corrosion resistance, perfect for roofing and exterior applications.

Pre-painted Sheets: Aesthetic appeal and extra protection, suitable for architectural projects.

Stainless Sheets: Excellent corrosion and heat resistance, crucial in food and chemical sectors.

Checker Plates: Anti-slip surfaces used in flooring, stairs, and industrial settings.

What Is a Steel Service Center?

A steel service center is a specialized facility that stocks metal sheets and related products, providing value-added services such as:

Slitting and shearing

Surface treatments (galvanizing, coating)

Custom fabrication

Packaging and logistics support

These centers act as a vital link between steel mills and end-users, ensuring the delivery of customized, production-ready materials.

Advantages of Partnering with a Steel Service Center

Material Availability: Access to a wide range of metal sheets reduces lead times.

Customization: Precision cutting and shaping tailored to project needs.

Cost Efficiency: Minimizes waste and lowers in-house processing costs.

Technical Expertise: Expert guidance on selecting the right materials and methods.

Logistics Support: Streamlined supply chain and reliable delivery.

Applications of Metal Sheets from Service Centers

Construction (beams, columns, roofing, cladding)

Automotive manufacturing (body panels, chassis)

Industrial machinery (components, tanks)

Agricultural equipment (frames, panels)

Energy sector (pipelines, wind towers)

Infrastructure (bridges, tunnels)