- Ana Sayfa

- Special Shaped Profiles

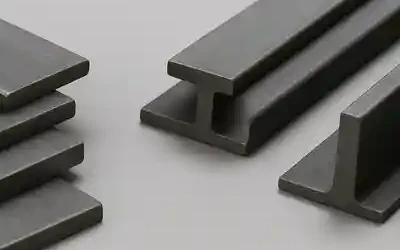

Special Shaped Profiles

Special Shaped Profiles for Custom Engineered Solutions

HL Metal designs, sources and processes special shaped profiles with tailored cross-sections beyond standard SHS, RHS, CHS and beams. Using carbon steel, stainless steel, aluminium and other alloys, we help engineers and architects realise unique geometries, weight-optimised structures and high-performance components.

What Are Special Shaped Profiles?

Special Shaped Profiles are metallic profiles produced with non-standard cross-sections and geometries. They are designed to meet specific mechanical, functional or aesthetic requirements that cannot be covered by conventional hollow sections or beams.

- Tailor-made cross-sections developed for your drawing or 3D model

- Complex contours, asymmetrical designs and hybrid shapes

- Produced by hot rolling, cold drawing, extrusion, laser cutting or combined processes

These profiles are frequently co-engineered between HL Metal and the customer, ensuring that strength, tolerances and fabrication details perfectly match the final application.

Related HL Metal Products & Services

- Square Hollow Sections (SHS)

- Rectangular Hollow Sections (RHS)

- Stainless Steel Hollow Sections

- Stainless Steel Sheets & Plates

- Painted Hollow Sections

For transforming special profiles into ready-to-assemble components, discover our CNC laser cutting, CNC plasma cutting, guillotine shearing and press brake bending capabilities.

Types of Special Shaped Profiles

Special shaped profiles cover a wide family of custom-designed sections used in construction, machinery, transportation and architectural applications.

Typical examples of special profiles supplied by HL Metal include:

- T-shaped, Z-shaped and L-shaped steel profiles

- Omega profiles and hat-shaped channels

- Special channels and asymmetrical sections

- Complex hollow sections with multiple cavities

- Custom rail and guiding profiles

- Special flange and edge-stiffened profiles

- Thin-wall or thick-wall hybrid shapes for weight optimisation

Each project can have its own unique geometry. We review your technical drawings and loading conditions to recommend the most suitable shape, material and production route.

Materials for Special Profiles

Special profiles can be produced from a broad range of metals, including:

- Carbon steel (S235, S275, S355 and others)

- Stainless steel – austenitic, ferritic, martensitic and duplex grades

- Galvanized steel for additional corrosion protection

- Aluminium and aluminium alloys for lightweight structures

- Brass or copper alloys for decorative and conductive purposes

For multi-material designs, we can combine profiles with laser cutting, welding and bolted joints to achieve hybrid constructions.

Manufacturing Processes for Special Shaped Profiles

Depending on the profile geometry, quantity and material, different manufacturing technologies can be used. HL Metal works with mills and processors that apply the following methods:

- Hot rolling: Ideal for large, high-strength profiles. Heated billets or slabs are rolled into the desired shape using dedicated roll passes.

- Cold drawing / cold rolling: Used where tight tolerances, smooth surfaces and higher mechanical strength are required, e.g. automotive or machinery components.

- Extrusion (aluminium and soft metals): Material is pushed through a custom die to create complex shapes with excellent dimensional repetition.

- Laser cutting & CNC machining: Suited for small to medium batches, prototypes or highly intricate designs that need precision slots, holes and contours.

- Welding & assembly: Multi-part profiles and hybrid structures can be built by combining cut plates, hollow sections and stiffeners with certified welding procedures.

- Finishing operations: Shot blasting, deburring, painting, galvanizing or polishing to meet corrosion, aesthetic and safety requirements.

Advantages of Special Shaped Profiles

Special shaped profiles offer clear benefits compared to using multiple standard sections:

- Design flexibility: Engineers can move beyond standard geometries and design profiles exactly around the forces and functional needs.

- Material efficiency: Tailored thickness and shape reduce unnecessary material, lowering both weight and cost.

- Performance optimisation: Cross-sections can be engineered to strengthen critical areas, improve stiffness or integrate guiding and fastening features.

- Reduced assembly costs: Functions that previously required several welded or bolted parts can be integrated into a single profile, shortening assembly time.

- Aesthetic customisation: In architectural projects, special profiles support distinctive facades, framing details and visible steel structures.

- Better integration: Profiles can be designed to match cladding systems, glazing interfaces, gasket grooves or cable management paths.

For OEMs and project owners, this means lighter, smarter and more competitive designs with a faster route from drawing to final product.

Industrial Applications of Special Shaped Profiles

Special shaped profiles serve a wide range of industries that require customised strength, form and function.

Construction & Architecture

- Facade and curtain wall sub-structures

- Window and door frames, glazing profiles

- Decorative trims, sun-shading and canopy systems

- Architectural staircases and balustrade supports

- Lightweight structural components and stiffeners

Transportation & Mobility

- Railcar and wagon components

- Bus and truck body frames and roof bows

- Automotive reinforcement profiles

- Lightweight aluminium sections for trailers

- Special profiles for aerospace support structures

Machinery, Energy & Infrastructure

- Conveyor frames and machinery housings

- Guiding and rail profiles for automation systems

- Wind turbine and solar panel supporting components

- Transmission tower and substation details

- Oil & gas, petrochemical and process plant structures

In addition, special shaped profiles are widely used in furniture, shelving, office partitions and consumer products, combining aesthetics with lightweight, functional designs. For more standardised solutions, you may also review our hot rolled steel sheets, galvanized sheets, cold rolled sheets and chequered plates.

Why Choose HL Metal for Special Shaped Profiles?

HL Metal Demir Çelik Sanayi combines technical know-how, service center flexibility and export experience to support demanding special profile projects.

- Advanced engineering support: Our team reviews your CAD drawings, loading requirements and fabrication route to help define an optimum profile design.

- Diverse material range: Carbon steel, stainless steel, galvanized steel, aluminium and other alloys for different environments and weight targets.

- Certified quality: Products can comply with ASTM, EN, DIN and ISO standards, with EN 10204 3.1 certificates available on request.

- Flexible batch sizes: From prototype and trial batches to full industrial series production.

- Global export expertise: Experience in packing, container loading, documentation and shipment to ports in Europe, Middle East, North Africa and South America.

- Integrated processing: Cut-to-length, drilling, slotting, bending and welding, so you receive profiles as close as possible to final part geometry.

Working with HL Metal means having a single partner from profile design and material selection to processing and export logistics.

Market Trends & Innovations in Special Shaped Profiles

Global demand for special shaped profiles is rising as industries aim for lighter structures, improved energy efficiency and smarter integration of functions. Several trends are driving this growth:

- Sustainability focus: Lightweight, recyclable and durable materials help reduce lifecycle emissions and support green building and ESG targets.

- Smart manufacturing: Industry 4.0 tools such as automated inspection, nesting optimisation and digital twins improve quality and shorten development cycles.

- Urbanisation & infrastructure: Expanding cities and new transport corridors require specialised components that fit tight design envelopes.

- Renewable energy growth: Wind, solar and energy storage projects increasingly rely on project-specific profiles to optimise installation and maintenance.

By partnering with a supplier experienced in custom geometries, processing and export like HL Metal, project owners can keep pace with these trends while maintaining cost control and technical reliability.

Special Shaped Profiles SEO Focus

HL Metal is a special shaped profiles supplier in Turkey providing custom metal profiles, non-standard steel sections, omega profiles, hat profiles, T and Z profiles, complex hollow sections and hybrid shapes for export projects. Typical queries: special shaped profiles manufacturer, custom steel profiles Turkey, omega steel profile supplier, non-standard steel sections for architecture and machinery.

special shaped profiles supplier Turkey, custom metal profiles Istanbul, custom steel sections for construction, omega profile manufacturer, hat profile steel, special T profile, special Z profile, complex hollow section design, custom stainless profiles, aluminium special shaped profiles, non-standard steel profiles export, tailored steel sections for machinery, HL Metal special profiles

Need Special Shaped Profiles for Your Next Project?

Share your drawings, 3D models, target material and annual usage. HL Metal will prepare a tailored proposal for special shaped profiles, including technical recommendations, pricing, lead time and export packing details – ready for international shipment.

Special Shaped Profiles, Custom Steel Profiles

At HL Metal Demir Çelik Sanayi, we proudly stand as a leading special shaped profiles supplier, delivering precision solutions for a wide range of industrial and architectural projects. As an experienced custom metal profiles manufacturer, we specialize in producing unique, non-standard geometries that meet the most demanding technical requirements.

Our portfolio includes precision-engineered steel profiles, crafted with advanced production technologies to ensure exact tolerances, high strength, and superior surface finishes. For clients seeking corrosion resistance and aesthetic appeal, we offer stainless steel special profiles designed for both heavy-duty and decorative applications. In addition, our aluminum extrusion profiles provide lightweight yet robust solutions, ideal for industries ranging from aerospace to furniture manufacturing.

Custom Shaped Steel Profiles, Special Steel Profiles

We also cater to the needs of the construction sector with architectural metal profiles, combining design flexibility with structural integrity. Whether you are designing facades, curtain walls, or decorative frameworks, our products help bring complex architectural visions to life.

As a provider of industrial custom profiles, we deliver tailored components for machinery, transport systems, energy infrastructure, and beyond. Our special profile fabrication services ensure that each project receives personalized attention — from prototype development to mass production — guaranteeing that specifications are precisely met.

With expertise in high-strength steel custom sections, HL Metal Demir Çelik Sanayi supports critical applications where durability and performance are paramount. As a trusted metal profile exporter in Turkey, we manage international shipments, providing certified quality, reliable logistics, and comprehensive documentation.