- Ana Sayfa

- Sheet Metal Punching

Sheet Metal Punching

Sheet Metal Punching

In high-mix, high-volume sheet metal operations, sheet metal punching remains a cornerstone because it converts raw sheets into functional parts with exceptional throughput and consistent dimensional control. Mechanical impact, governed by tool geometry and die clearance, creates crisp holes, slots and formed features without a heat-affected zone.

With modern CNC controls, servo-electric drives, intelligent nesting and automated tool management, CNC punching scales from prototypes to lights-out production while preserving edge quality and flatness required by downstream press brake bending, welding, coating or assembly. It also complements CNC laser cutting and CNC plasma cutting in a complete sheet metal fabrication cell.

Principles of Punching

Mechanics of Deformation & Fracture

During sheet metal punching, the punch descends into the sheet and compresses material against the die opening. Elastic compression transitions to plastic flow, followed by a shear fracture that propagates around the tool perimeter.

The resulting edge typically shows a rollover entry, a bright burnished zone, a granular fracture band and a minimal burr whose magnitude reflects die clearance and punch sharpness.

Energy Transfer & Stroke Profile

In a modern punch press operation, stored kinetic energy from a flywheel or controlled torque from a servo-electric drive is transferred to the ram. The stroke profile, dwell control at bottom dead center and return acceleration govern hole roundness, slug ejection and die wear.

Programmable stroke depth limits contact time to reduce galling on soft alloys and work-hardening on stainless steels.

Implications for Downstream Processes

Because no thermal input is applied, bends form consistently, welds wet predictably and coatings adhere uniformly. This stability is a decisive advantage over thermal cutting when parts require tight bend radii, CNC press brake bending or cosmetic powder coatings with minimal edge prep.

Machine Architecture & Motion

Turret & Single-Station Presses

Turret punching uses an upper and lower turret loaded with multiple tools that index rapidly under CNC control. This architecture enables instant tool changes, mixed features on the same sheet and high throughput with limited operator intervention.

Single-station presses support larger or custom tools and can deliver extreme tonnage for thicker stock and special applications.

Drive Technologies

Hydraulic drives provide high force density and adjustable pressure profiles for thick gauges. Servo-electric drives deliver precise positional control, low noise and energy efficiency. Mechanical clutch-and-flywheel systems remain robust for simpler duty cycles where cost per stroke is critical.

Sheet Handling & Registration

Brush tables and vacuum assist reduce scratch risk on coated or anodized surfaces. Repositioning clamps allow processing sheets larger than the nominal working envelope, and integrated sheet skeleton management reduces operator exposure and improves takt time.

Tooling, Clearances & Edge Geometry

Punch & Die Selection

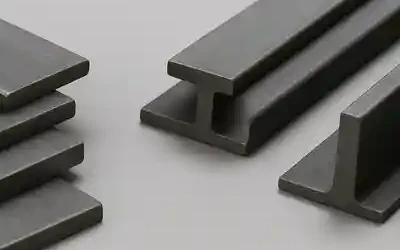

Punch tooling defines what the machine can produce. Round tools generate holes and knockouts; rectangle and obround tools create slots and tabs. Special forms add embosses, louvers, countersinks and bridges.

Coatings such as TiN or AlCrN mitigate galling on aluminum and heat-resistant steels while extending edge retention.

Clearance Strategy

Die clearance is the radial gap between punch and die. Smaller clearances reduce burr but increase cutting force and wear. Larger clearances lessen force yet promote roll-over and burr.

Recipe-based settings consider thickness, tensile strength and desired edge characteristics to balance force, quality and tool life.

Edge Conditions & Deburring

When cosmetic criteria are strict, micro-burrs are removed with belt finishing or brush deburring. Where permissible, deburring is minimized by keeping punches sharp, aligning dies, lubricating judiciously and optimizing clearance for each material class.

Capabilities & Feature Set

Holes, Slots & Arrays

Hole punching is the archetypal operation, but complex panels often rely on pattern arrays for ventilation, acoustics or aesthetics.

Perforation cutting by programmed stepping yields consistent pitch and edge quality at line rates thermal processes cannot match on thin gauge.

Forming & Embossing

Punch forming integrates shallow forms during the same setup, eliminating secondary presses. Louvers, dimples and bridge lances improve stiffness, airflow and fastener strategies without adding parts or welding time.

Nibbling & Contour Approximation

Where geometry is not purely prismatic, nibbling approximates curves by overlapping hits. Proper step size, lead-in strategy and edge conditioning can deliver near-laser aesthetics while retaining the no-HAZ advantages of mechanical cutting.

CNC Programming, Nesting & Process Control

Nesting for Yield & Takt

Advanced nesting aligns part families to standard sheet sizes, maximizes yield by sharing edges and groups tools to minimize turret rotation. Skeleton integrity is engineered to maintain sheet stability through the final hit while allowing clean break-out at the unload station.

Tool Paths & Micro-Joints

Programs specify hit order, plunge speeds, dwell and retract heights. Micro-joints preserve part integrity during repositioning and are trimmed at the brake or by final shear.

Tool life is extended by distributing hits across multiple stations of the same tool where available.

Closed-Loop Quality

On-machine probing, vision alignment and clamp force monitoring enable closed-loop corrections to back-gauge offsets or tool wear. SPC dashboards visualize length drift, burr height and punch load to initiate maintenance before defects escape.

Materials & Surface Conditions

Carbon & Low-Alloy Steel

These grades respond predictably in metal punching, providing bright burnish and limited burr at moderate forces. High-strength variants increase tonnage and may demand alternative clearances or coated tooling.

Stainless Steel

Austenitic stainless work-hardens quickly under impact; sharp tools, generous lubrication and slightly larger clearances prevent seizure and edge work-hardening that would complicate forming and cosmetic finishing.

Aluminum & Coated Sheet

Soft alloys risk smearing and galling. Polished punches, low-adhesion coatings and controlled clamp pressure protect surface films.

Painted or film-protected panels benefit from brush tables and non-marking support strategies, especially when integrated with downstream coating and shop primer operations.

Quality, Metrology & Typical Defects

Tolerances & Verification

With calibrated back-gauge systems and sharp tools, hole position tolerances of ±0.1–0.2 mm and length tolerances of ±0.2–0.5 mm are routine on thin-to-medium gauges. Thick plate tolerances are broader due to elastic recovery and fracture variability.

Defect Prevention

Burr arises from excessive clearance or dull punches. Roll-over increases with poor support or too-large gaps. Out-of-round holes point to misalignment or excessive wear.

Root causes are addressed by tool reconditioning, die realignment and recipe optimization in the CNC. First-article inspections establish reference samples and control plans.

Documentation & Traceability

Process data – stroke counts, tool IDs, material heats, operator credentials – can be exported to MES for ISO-compliant traceability and customer documentation.

Maintenance & Tooling Lifecycle

Preventive Strategies

Lubrication, turret alignment checks and clamp inspection prevent drift in hole position and edge quality. Servo or hydraulic system health is monitored via vibration and oil analysis to avoid unplanned stoppages.

Tool Rotation & Sharpening

Documented sharpening angles, micro-bevels and rotation patterns extend tool life. Coated tools require appropriate grinding media to preserve the coating integrity while restoring edge sharpness.

Comparison with Other Cutting Methods

CNC punching excels when parts require many holes, slots, louvers or embosses combined with straight trims. For freeform contours or thick plate, alternative processes may be more effective. The table summarizes practical trade-offs for engineering decisions.

| Method | Geometry Capability | Speed on Thin Sheet | Heat-Affected Zone | Edge Quality | Typical Thickness Range | Integrated Forms | Cost per Part | Best-Fit Scenarios |

|---|---|---|---|---|---|---|---|---|

| CNC Turret Punching | Holes, slots, rectangles, nibble contours | Very high | None | Clean shear edge; minor burr possible | Thin to medium sheet | Yes (louvers, embosses, knockouts) | Low | Panels with many holes & forms; high throughput |

| Laser Cutting | Freeform, tiny radii, intricate detail | High | Small HAZ | Excellent; dross if mis-tuned | Thin to medium plate | No (forms require secondary) | Medium | Complex profiles, tight nesting, variable mix |

| Plasma Cutting | Complex contours, larger kerf | Medium–High | Moderate HAZ | Good; more taper than laser | Medium to thick plate | No | Medium–Low | Structural plate & general fabrication |

| Waterjet | Freeform without thermal effects | Low–Medium | None | Excellent; minimal taper | Thin to very thick | No | High | Heat-sensitive or multi-material stacks |

| Shearing | Straight lines only | Very high | None | Clean; minimal burr with setup | Thin to heavy plate | No | Lowest | Rectangular blanks, squaring, panel prep |

| Metal Stamping (Progressive Die) | Fixed geometry at extreme rate | Ultra high | None | Excellent, die-defined | Thin to medium sheet | Yes (die-integrated) | Low at scale; high tooling | Mass production of one design |

Applications & Industry Use-Cases

Enclosures, HVAC & Electrical Panels

Long arrays of ventilation holes, accurate knockouts for conduit and stiffening embosses are created in a single setup. Panel flatness and burr control reduce finishing and ensure gasket sealing.

Automotive & Mobility

Brackets, reinforcement tabs and interior hardware leverage high positional accuracy and repeatability. Where appearance matters, deburring and brush finishing yield paint-ready edges.

Appliances & Consumer Electronics

High hole counts and decorative perforations call for CNC punch cutting with optimized nesting to maintain yield and protect cosmetic surfaces throughout handling.

Architecture & Acoustic Panels

Patterned perforation cutting enables visual designs and sound absorption strategies while keeping costs controlled on large panel runs.

Safety & Compliance

Safeguarding

Light curtains, interlocked guards and two-hand controls prevent access during stroke. Repositioning clamps and skeleton handling are designed to keep operators outside pinch zones.

Procedures

Lockout for tool changes, ergonomic sheet handling and PPE tuned to sharp edges reduce risk. Training emphasizes die alignment, slug evacuation and emergency stop routines.

Sustainability & Cost Model

Yield & Kerf Economics

Because kerf is essentially the die opening itself, material loss is limited to the slug, enabling high nesting density. Shared edges and optimized sequences reduce scrap and stroke count.

Energy & Noise

Servo-electric presses reduce idle consumption and noise compared with legacy hydraulics. Balanced lubrication plans minimize waste streams and improve shop air quality.

Total Cost of Ownership

Capital cost, tool inventory, sharpening cycles and operator skill form the cost envelope. For parts rich in holes and forms, punching offers the lowest cost per part relative to thermal processes that would require secondary forming steps.

FAQs

What differentiates punch press cutting from laser cutting?

Punching is mechanical and excels at repetitive holes, slots and integrated forms without heat. Laser is thermal and excels at freeform contours. Many plants combine both to play to each process’s strengths.

How is a stamping process different from turret punching?

Stamping uses dedicated dies that produce a fixed geometry at extremely high speed with very low unit cost but high tooling investment. Turret punching is flexible, tooling-light and ideal for variable mix or evolving designs.

Can cosmetic surfaces be protected during metal punching?

Yes. Use plastic films, brush tables and non-marring clamps. Adjust lubrication and clamp force to prevent witness marks on coated or anodized sheet.

What tolerance can I expect on CNC punching?

On thin galvanized or cold-rolled sheet, ±0.1–0.2 mm hole position and ±0.2–0.5 mm length are typical with healthy tooling, calibration and controlled material.

Related Services & Internal Links

- CNC laser cutting

- CNC plasma cutting

- Guillotine shearing

- Laser cutting for tubes & hollow sections

- Galvanizing coating

- Sandblasting, coating & shop primer

CNC punching can be combined with these cutting, forming and coating services to deliver fully processed, export-ready sheet metal assemblies from a single steel service center.

Request a Quote – Sheet Metal Punching

Please provide material grade, thickness, overall sheet size, part quantities, hole counts and any cosmetic requirements so we can select optimal tooling, clearances and routing for your project.

Our engineering team can integrate CNC turret punching with press brake bending, laser cutting, plasma cutting, galvanizing and surface coating into one coherent manufacturing plan.

Need High-Throughput CNC Punching?

Share your drawings and specifications to receive nesting suggestions, process recommendations and a detailed quotation for sheet metal punching and related services.

Contact HL Metal – Sheet Metal PunchingTurret Punching, Punch Press Cutting, Hole Punching

Turret Punching is one of the most efficient methods in modern sheet metal fabrication, allowing manufacturers to process large volumes of parts with speed and precision. By using advanced turrets with multiple tools, the machine can switch between operations without interruption, enabling complex geometries and repetitive features in a single cycle. Closely related, Punch Press Cutting is widely applied to produce straight and accurate cuts on thin and medium-gauge sheets, minimizing waste and ensuring cost efficiency.

Hole Punching, Metal Stamping, Perforation Cutting

For designs requiring high-density perforations, Hole Punching and Perforation Cutting deliver consistent results with minimal distortion. These techniques are especially important in ventilation panels, filters, and architectural screens. In addition, Metal Stamping is frequently combined with punching to form shapes, bends, and embosses directly on the sheet surface, adding both functionality and visual appeal.

Punch Forming, CNC Punch Cutting, Punch Tooling

Advanced machines also allow Punch Forming and CNC Punch Cutting, which expand design possibilities by integrating forming and cutting in one setup. With the use of dedicated Punch Tooling, manufacturers can achieve louvers, countersinks, and custom slots with excellent repeatability. Furthermore, the Stamping Process and Punch Press Operation provide flexibility for both high-volume production runs and small batch projects, making punching a versatile solution for industries such as construction, automotive, and electronics.