- Ana Sayfa

- Rolled Steel Products

Rolled Steel Products

Rolled Steel Products

Rolled steel products refer to materials that come in various diameters and feature perforated characteristics. These products are particularly prominent in applications where metals need to be transformed directly into wire form. The manufacturing of rolled products varies depending on their intended use, with differences in size and volume tailored to specific applications. Both hand-operated and motor-driven types of rolled products are available to suit various operational needs.

When there is a need to reduce wire diameters, the perforations on the product can be quickly adjusted, allowing for efficient downsizing.

[Click here to explore rolled steel product types.]

Steel and rebar prices may vary depending on the brand and model of the product. Rolled products are known for their wide range of applications and are considered highly reliable materials. These profiles can be manufactured using either hot or cold rolling processes. If you’re curious about what a square solid bar is and how it’s used, continue reading our article for more details.

As metal passes through rollers, the gap between the rollers can be adjusted depending on the incoming thickness of the material. The thickness of the rolled metal at the exit point will decrease accordingly. HL Metal, a trusted manufacturer of reinforcing bars, provides reliable solutions for your rolled steel product needs.

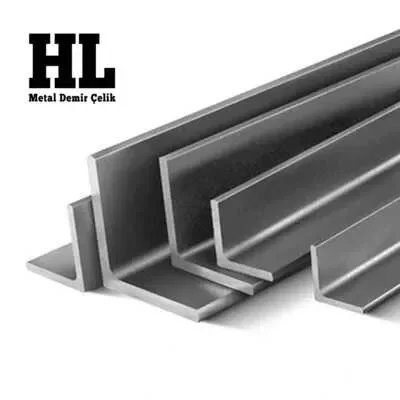

Angle Iron - HL Metal Excellence

Angle irons, a common type of rolled product, are also offered by HL Metal. But what is the purpose of angle irons, and what should you consider when purchasing them?

Properly manufactured angle irons ensure straight and durable edges. Since these components are often integrated into central structural areas, they are exposed to high-impact forces. Using angle irons helps prevent damage and injury, making them a preferred solution for structural reinforcement.

If you require steel products, HL Metal is your dependable partner. Reach out to our expert team for professional support and detailed information on all types of rolled products. You can contact us directly.

Rolled Steel Products

Rolled steel products are materials shaped through the rolling process, which involves deforming metals or alloys by passing them between rollers at a specific temperature (hot or cold) to reduce thickness and achieve the desired shape.

Types of Rolled Steel Products:

Flat Rolled Products:

Sheet (hot-rolled, cold-rolled, galvanized, painted, etc.)

Plate

Strip

Long Rolled Products:

Rebar (ribbed or plain)

Profiles (NPU, NPI, HEA, HEB, IPE, etc.)

Rods and wire products

Special Rolled Products:

Railway rails

Special alloy steels

Pipes (seamless and welded)

Rolling is a crucial process in the steel industry and is widely used in various sectors such as construction, automotive, machinery, and shipbuilding.

Characteristics of Rolled Steel Products

Metals produced through rolling processes acquire specific mechanical and physical properties. These characteristics vary depending on the production method and intended application. Below are the general properties of rolled steel products:

1. Mechanical Properties

Strength: Offers high durability and resistance to mechanical stress.

Ductility and Toughness: Cold-rolled products are harder, while hot-rolled products are more ductile.

Wear Resistance: When surface quality is enhanced after rolling, resistance to wear is significantly improved.

2. Physical and Chemical Properties

Surface Finish: Cold-rolled products have a smoother and more refined surface compared to hot-rolled ones.

Corrosion Resistance: Can be enhanced through galvanizing or special coatings.

Density and Weight: Vary depending on the material type and cross-sectional shape.

3. Manufacturability and Processability

Weldability: Most rolled products can be easily welded using suitable techniques.

Formability: Due to their hardness, cold-rolled products are less suitable for forming compared to hot-rolled ones.

Machinability: High-hardness rolled steels may cause increased tool wear during machining processes.

4. Application-Based Properties

Construction Industry: Requires high-strength and ductile materials.

Automotive Industry: Uses cold-rolled materials that are lightweight and highly durable.

Machinery Manufacturing: Demands materials with high mechanical strength and good machinability.

Types of Rolled Steel Products

Steel products are classified into three main categories based on their manufacturing method and area of use: flat products, long products, and special products.

Flat Rolled Products

These products are commonly used in the form of sheets and plates across many industries.

Hot-Rolled Sheet: Thick and high-strength; widely used in construction and shipbuilding.

Cold-Rolled Sheet: Thinner and smoother surface; ideal for automotive and white goods industries.

Galvanized Sheet: Corrosion-resistant; used in roofing and exterior cladding applications.

Pre-painted Sheet: Painted for aesthetic purposes and enhanced corrosion resistance.

Steel Plates: Commonly used in shipbuilding, pressure vessels, and machinery manufacturing.

Long Rolled Products

Typically in the form of bars and profiles, these products play a major role in the construction industry.

Rebars (Ribbed & Plain): Used for reinforcement in reinforced concrete structures.

Structural Steel Profiles:

NPU, NPI, IPE, HEA, HEB: Preferred for steel construction frameworks.

Angle Bars (L Profiles): Used in machinery and structural applications.

U, I, T Sections: Commonly used in steel framing systems.

Wire and Rod Products:

Used in wire drawing, welding electrodes, and spring production.

Special Rolled Products

These are designed for specific applications and typically made from special alloys.

Railway Rails: Manufactured from high-strength steel.

Seamless and Welded Pipes: Used in petroleum, natural gas, and high-pressure vessels.

Stainless Steel Products: Widely used in chemical, food, and medical equipment industries.