- Ana Sayfa

- Our Services

Our Services

Our Services – Steel Service Center

Welcome to our integrated Steel Service Center—a production partner that unifies sourcing, Steel Processing and Distribution, finishing, and export-ready logistics. Acting as a Full-Line Steel Service Center, we deliver a single, traceable workflow from coil to finished assembly. Our operation also functions as a responsive Metal Service Center, a precision-focused Steel Processing Center, and an agile Steel Distribution Center. From Steel Cutting Services and Steel Slitting Services to Steel Coil Processing, Steel Fabrication Services, and project documentation, we align scope, schedule, and quality to your program goals.

Quick Navigation

- Coil Processing & Conversion

- Cut to Length From Coil

- Steel Slitting Services

- Steel Coil to Sheet Cutting

- Cutting Technologies (Laser, Plasma, Shearing)

- Forming, Punching & Machining

- Surface Prep & Coatings

- Quality, Certificates & Traceability

- Logistics, Pricing & Commercials

- FAQ & Buyer’s Checklist

- Request a Quote

Looking for a Steel Service Center Near Me? Our regional coverage, consolidated freight, and mixed-SKU kitting keep transport time predictable. For ready-to-use materials, you can Buy Steel Sheets from Service Center in standard packs or request Custom Size Steel Sheets from Coil to match your nests. When cost comparisons matter, we provide clarity on Steel Service Center Prices, a Custom Steel Processing Price, and any combined Steel Cutting and Slitting Price.

Coil Processing & Conversion

As a dedicated Steel Coil Processing Supplier and experienced Steel Service Center Manufacturer, we convert prime coils into sheets or custom strips while controlling flatness, burr, edge wave, and camber. Our Steel Supply and Processing model accelerates flow: material arrives, is processed, labeled, and shipped with a single traceability thread. For projects that combine multiple operations—such as Steel Coil Processing followed by forming, Metal Processing and Fabrication, then finishing—keeping everything under one schedule sharply reduces handoffs.

Cut to Length From Coil

Our Cut to Length From Coil service (also known as Cut to Length Steel Service) converts incoming coils into consistent, flat sheets sized for lasers, presses, and bending cells. We align sheet length tolerances to your nesting plans and storage footprint. Where required, we add PE film or interleaving, and we prepare edges for downstream aesthetic requirements. Learn more on our dedicated page: Cut to Length From Coil.

Steel Slitting Services

For roll-forming, tube mills, and stamping lines, our Steel Slitting Services deliver precise strip widths with controlled burr and camber. When geometry demands narrow tolerances, we run Custom Steel Coil Slitting strategies. Lane-based banding and barcode labels keep every strip identifiable through your value stream. Visit: Steel Slitting Services.

Steel Coil to Sheet Cutting

Not every component uses strip. Many applications require sheets before cutting or forming; our Steel Coil to Sheet Cutting path balances throughput with surface protection. For buyers comparing options to Buy Steel Sheets from Service Center, we offer standard sizes and Custom Size Steel Sheets from Coil for optimized nests. See: Steel Coil to Sheet Cutting.

Cutting Technologies — Accuracy, Edge Quality & Throughput

Selecting the right technology depends on geometry, material thickness, tolerance, and budget. We offer a complete menu—Steel Laser Cutting Service via CNC Laser Cutting, Steel Plasma Cutting Service via CNC Plasma Cutting, and Steel Sheet Shearing through Guillotine Cutting. Using a multi-technology approach can lower cost per part while protecting functional criteria.

CNC Laser Cutting

Our CNC Laser Cutting platforms deliver tight-tolerance contours and clean edges for enclosures, guards, and precision mechanisms. As part of our Precision Steel Cutting Services, we import DXF/DWG, optimize nests, and report material utilization. This route sits at the heart of our High Quality Steel Processing Services for accuracy-critical components. Explore details: CNC Laser Cutting and Steel Laser Cutting Service.

CNC Plasma Cutting

For thicker plates and large-format parts, CNC Plasma Cutting is efficient and robust. Our Steel Plasma Cutting Service includes bevel cutting and part marking to speed fit-up and welding orientation. We control heat input to manage distortion across large panels and structural components. More info: CNC Plasma Cutting.

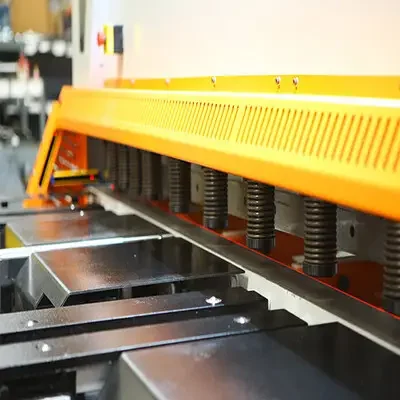

Steel Sheet Shearing / Guillotine Cutting

Rectangular blanks and base plates are often best produced via Steel Sheet Shearing with Guillotine Cutting. This is especially effective for high-mix, moderate-volume programs where speed and economy matter. Combined with Press Brake Bending Services, sheared blanks can move directly into forming cells.

Forming, Metal Punching & Machining

After cutting, parts are formed, punched, and machined to spec. Our forming playbooks document tooling, bend allowances, and inspection steps; our punching and machining stages add critical features and final tolerance control—ready for assembly or coating.

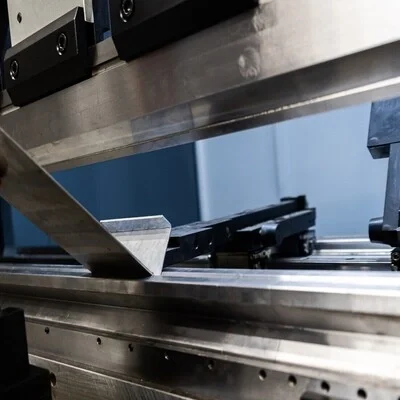

Press Brake Bending Services

Press Brake Bending Services cover simple flanges to complex multi-bend sequences. Back-gauging, custom tooling, and statistical checks ensure repeatability. We lock angle verification routines and bend deductions to protect dimensional targets across batches and revisions. Learn more: Press Brake Bending Services.

Metal Punching & Machining Services

For high-throughput patterns, Metal Punching delivers speed; for precision-critical features, Machining Services (milling, drilling, tapping, countersinking) ensure positional accuracy and finish requirements. Combining both often yields the best balance of cycle time and quality. Details: Metal Punching and Machining Services.

Surface Preparation & Coatings

Durability and aesthetics depend on qualified preparation and finishing. We tailor routes to the operating environment and maintenance expectations, documenting adhesion and thickness where required.

Sandblasting and Painting

With Sandblasting and Painting, we achieve the cleanliness level and surface profile specified by your coating system. We record thickness and adhesion tests per lot and maintain color consistency for visual alignment across assemblies. Visit: Sandblasting and Painting.

Galvanizing

For harsh environments, Galvanizing provides long-term protection. We coordinate vent/drain features for hot-dip processes, verify zinc thickness, and manage post-treatment touch-ups. Coating records support audits and warranty documentation. See: Galvanizing.

Quality Assurance, Certificates & Traceability

Our quality framework prevents issues rather than merely detecting them. Each part number carries a control plan aligned with risk and tolerance. We supply mill test certificates, coating reports, and packing lists that preserve the traceability chain from heat to shipment. This discipline underpins our reputation for High Quality Steel Processing Services across sectors.

Precision Steel Cutting Services

Whether we deliver intricate laser profiles or thick plasma-cut plates, our Precision Steel Cutting Services verify critical-to-function features with calibrated instruments. First-article approvals and revision control protect your configuration integrity, especially for serialized production.

Documentation & Labels

Labels include part number, revision, batch, and project reference. For audits, we provide certificates and inspection summaries on request. This rigor simplifies receiving, speeds line-side identification, and reduces rework risks.

Logistics, Scheduling & Commercials

Acting as an Industrial Steel Service Center, we align production slots to your milestones and coordinate EXW, FCA, FOB, CFR/CIF deliveries. Our kitting model consolidates mixed SKUs, reducing receiving time and internal travel at your plant. When comparing Steel Service Center Prices, a Custom Steel Processing Price, or a combined Steel Cutting and Slitting Price, we provide itemized proposals that clarify inclusions, tolerances, packaging, and documentation.

Affordable Steel Service Center – Without Compromise

Being an Affordable Steel Service Center is not about the lowest unit price only. Integrated services reduce hidden costs: fewer handoffs, less scrap, fewer line stoppages, and smoother audits. The outcome is lower total landed cost with consistent quality.

Cross-Links to Detailed Service Pages

- Steel Service Center & Steel Processing Center

- Steel Distribution Center & Steel Fabrication Services

- CNC Laser Cutting & CNC Plasma Cutting

- Guillotine Cutting & Press Brake Bending Services

- Metal Punching & Machining Services

- Steel Slitting Services & Cut to Length From Coil

- Sandblasting and Painting & Galvanizing

- Buy Steel Sheets from Service Center & Custom Size Steel Sheets from Coil

FAQ & Buyer’s Checklist

What information ensures a fast, accurate quote?

Share material grade and standard, thickness/width/length or coil specs, drawings (DXF/DWG/PDF), tolerances, surface requirements, quantity, delivery terms, and any certificates you need. We then propose routes—e.g., Steel Coil Processing with Cut to Length From Coil or Steel Coil to Sheet Cutting, plus Steel Slitting Services, Steel Laser Cutting Service/CNC Laser Cutting, Steel Plasma Cutting Service/CNC Plasma Cutting, Guillotine Cutting, Press Brake Bending Services, Metal Punching, Machining Services, Sandblasting and Painting, and Galvanizing.

How do you support scalability and repeatability?

We lock process parameters and inspection frequency after first-article approval. Capacity is flexed to ramp from prototype to serial production without losing documentation integrity.

Buyer’s Checklist

- Confirm provider is a real Full-Line Steel Service Center with cutting, forming, machining, and finishing in-house.

- Verify capability for Steel Coil Cutting Services, Steel Coil Slitting Services, and Steel Sheet Shearing.

- Assess technology fit: Steel Laser Cutting Service/CNC Laser Cutting vs. Steel Plasma Cutting Service/CNC Plasma Cutting.

- Check forming (Press Brake Bending Services), feature creation (Metal Punching, Machining Services), and finishing (Sandblasting and Painting, Galvanizing).

- Ensure documentation, labeling, and traceability align with your audit needs.

Request a Quote

Ready to streamline supply? Visit Request for Quotation and upload your drawings and specs. We will compare alternatives across Steel Cutting Services, Steel Slitting Services, Steel Coil Processing, Cut to Length From Coil, Steel Coil to Sheet Cutting, CNC Laser Cutting, CNC Plasma Cutting, Guillotine Cutting, Press Brake Bending Services, Metal Punching, Machining Services, Sandblasting and Painting, and Galvanizing to hit your quality, schedule, and budget targets.

High Quality Steel Processing Services

We operate as a Steel Service Center, Metal Service Center, Steel Processing Center, and Steel Distribution Center delivering Steel Processing and Distribution with a Full-Line Steel Service Center footprint. Our menu includes Steel Cutting Services, Steel Slitting Services, Steel Coil Processing, Custom Steel Service Center workflows, Steel Fabrication Services, Cut to Length Steel Service, Steel Plate Processing Center competences, Steel Coil to Sheet Cutting, Steel Sheet Shearing.

Steel Laser Cutting Services

Steel Laser Cutting Service (CNC Laser Cutting), Steel Plasma Cutting Service (CNC Plasma Cutting), Guillotine Cutting, Press Brake Bending Services, Metal Processing and Fabrication, Metal Punching, and Machining Services.

For protection and finish we offer Sandblasting and Painting and Galvanizing. Commercially we provide clarity on Steel Service Center Prices, a Custom Steel Processing Price, and a Steel Cutting and Slitting Price. Buyers can Buy Steel Sheets from Service Center and order Custom Size Steel Sheets from Coil. If you’re searching for a Steel Service Center Near Me, our Industrial Steel Service Center coverage and experience as a Steel Coil Processing Supplier and Steel Service Center Manufacturer ensure repeatable results with an Affordable Steel Service Center total cost.

Back to top