- Ana Sayfa

- IPE Sections or IPE Beams

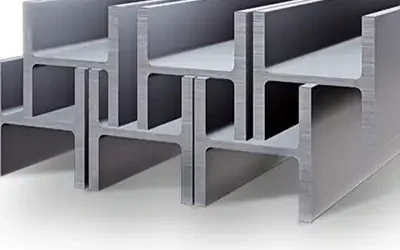

IPE Sections or IPE Beams

IPE Beams – European I-Beam Sizes, Dimensions & Weight Chart

IPE beam, also known as European I-beam or I-Profile beam, is a structural steel I-section with parallel flanges. The abbreviation IPE stands for “I-section Parallel European” and defines its standardized geometry.

Thanks to its excellent strength-to-weight ratio, IPE steel beam is widely used in construction, civil engineering, machinery and metal fabrication. IPE sections are part of the European standard EN 10365 and manufactured in dimensions typically ranging from IPE 80 to IPE 600, where the number denotes the nominal height in millimetres.

HL Metal Demir Çelik supplies a full range of IPE beams in S235JR, S275JR and S355JR steel grades, produced according to EN 10025 and delivered with EN 10204 3.1 / 2.2 Mill Test Certificates.

IPE Beams: European Parallel Flange I-Sections

IPE beams belong to the family of European I-section parallel flange beams. Their geometry is optimized for bending about the strong axis while keeping the weight relatively low compared to heavier H profiles such as HEA, HEB and HEM.

With standardized dimensions and sectional properties defined in EN 10365, IPE steel sections simplify structural design and fabrication, making them a preferred choice for engineers, architects and steel constructors worldwide.

IPE Sizes, Dimensions & Weight Chart

The table below provides typical IPE beam sizes with corresponding height, flange width, web / flange thickness (t) and weight per 12 m length, useful for quick tonnage and cost estimation.

| IPE Size | Height h (mm) | Flange Width b (mm) | Thickness t (mm) | Weight (kg / 12 m) |

|---|---|---|---|---|

| IPE 100 Beam | 100 | 55 | 4.10 | 98 |

| IPE 120 Beam | 120 | 64 | 4.40 | 126 |

| IPE 140 Beam | 140 | 73 | 4.70 | 156 |

| IPE 160 Beam | 160 | 82 | 5.00 | 191 |

| IPE 180 Beam | 180 | 91 | 5.30 | 227 |

| IPE 200 Beam | 200 | 100 | 5.60 | 271 |

| IPE 220 Beam | 220 | 110 | 5.90 | 317 |

| IPE 240 Beam | 240 | 120 | 6.20 | 371 |

| IPE 270 Beam | 270 | 135 | 6.60 | 437 |

| IPE 300 Beam | 300 | 150 | 7.10 | 511 |

| IPE 330 Beam | 330 | 160 | 7.50 | 594 |

| IPE 360 Beam | 360 | 170 | 8.00 | 691 |

| IPE 400 Beam | 400 | 180 | 8.60 | 802 |

| IPE 450 Beam | 450 | 190 | 9.40 | 939 |

| IPE 500 Beam | 500 | 200 | 10.20 | 1097 |

| IPE 550 Beam | 550 | 210 | 11.10 | 1283 |

| IPE 600 Beam | 600 | 220 | 12.00 | 1476 |

A full IPE weight chart including kg/m, section area, moments of inertia and section modulus can be provided from our technical catalogues for detailed design and optimization.

Applications of IPE Steel Beams

IPE steel beams are extremely versatile and used in a wide variety of structural and industrial applications:

- Residential and commercial buildings

- Industrial halls and warehouses

- Bridges, flyovers and walkways

- Steel frame structures and portal frames

- Machinery bases and platforms

- Racking systems and mezzanine floors

- Shipbuilding and infrastructure projects

Their standardization, predictable performance and availability make IPE beams a go-to choice for designers seeking both structural efficiency and cost control.

Advantages of IPE Beams

- Efficient load distribution across the web and flanges

- Standardized sizing simplifies engineering calculations and design

- Cost-effective solution for medium-span beams and floor systems

- Lighter than HEA and HEB beams for similar span requirements

- Available in multiple steel grades and surface finishes

- Excellent for welding, bolted connections and prefabrication

Key Features & Technical Properties

| Property | Description |

|---|---|

| Shape | I-shaped with parallel flanges |

| Material Grades | Common grades: S235JR, S275JR, S355JR |

| Standard | EN 10365 (geometrical standard for steel sections) |

| Manufacturing | Hot rolled, typically in carbon structural steel |

| Surface Treatment | Black (as-rolled), galvanized, primed or painted |

Steel Grades for IPE Beams

The most common structural grades used in IPE beam manufacturing are:

- S235JR – general structural steel (yield strength ≈ 235 MPa) for standard load conditions.

- S275JR – slightly stronger, suitable for more demanding loads and longer spans.

- S355JR – high strength (yield strength ≈ 355 MPa), used in critical load-bearing applications and more slender structures.

All grades conform to EN 10025-2 and can be supplied with EN 10204 3.1 or 2.2 MTCs to ensure full traceability and compliance.

IPE Beam vs IPN, HEA, HEB

Selecting the right beam profile often involves comparing IPE beams with alternatives such as IPN, HEA and HEB. The table below highlights typical differences:

| Type | Flange Width | Weight | Usage |

|---|---|---|---|

| IPE | Narrow | Light | Beams, purlins, general framing |

| IPN | Very narrow (tapered flanges) | Lighter | Outdated or light-duty applications |

| HEA | Wide | Medium | Columns, bracing, general structures |

| HEB | Very wide | Heavy | Load-bearing columns, heavy-duty structures |

In summary, IPE beams are ideal for medium-span beams and general framing where a lighter, efficient section is required, while HEA and HEB provide higher capacity for heavily loaded columns and frames.

Surface Finishes & Treatments

Depending on project and environmental requirements, IPE beams can be supplied with several surface conditions:

- Black steel (as-rolled): economical option for internal or further-processed beams.

- Hot-dip galvanized: for long-term corrosion protection in outdoor or humid environments.

- Primed / painted: for aesthetic appearance and additional protection.

- Shot-blasted and coated: for marine, offshore or aggressive industrial atmospheres.

High-Quality IPE Steel Beams from HL Metal

IPE (European I-beams) supplied by HL Metal are used in structural steelwork, construction engineering and industrial fabrication worldwide. With optimized cross-section and lighter weight compared to heavy H profiles, IPE beams provide excellent bending resistance, easy weldability and efficient load distribution.

HL Metal supplies a full range of IPE beams from IPE 80 to IPE 600 in steel grades S235JR, S275JR and S355JR, produced according to EN 10025. Upon request, beams can be delivered with:

- Precise cutting to length

- Drilling, copes and end preparation

- Shot blasting and priming

- Export-ready bundling, labeling and packaging

Each beam is shipped with its corresponding EN 10204 3.1 / 2.2 Mill Test Certificate, ensuring full traceability and compliance with project specifications.

Whether you are supplying a construction site, fabricating steel structures or preparing export-based projects, HL Metal offers fast delivery, competitive pricing and technical support for all IPE beam requirements.

Related Structural Sections & Internal Links

Complement your IPE beams with other structural sections from HL Metal:

- HEA Beams – Wide Flange Beams

- HEB Beams – H Shape Steel Structure

- HEM Beams – Heavy Wide Flange Beams

- UPE Sections – Parallel Flange Channels

- UPN Profiles – Taper Flange Channels

- NPI / IPN Beams – European I-Sections

- Square Hollow Sections – SHS

- Steel Weight Calculator – Beams, Channels, Hollow Sections

Request an IPE Beam Quotation

If you are looking for a reliable IPE beam supplier or structural steel distributor for your next project, HL Metal Demir Çelik is ready to help.

Share your beam list (sizes, lengths, grades), delivery terms and destination, and our export team will prepare a competitive, optimized offer for IPE steel beams and other structural sections.

Contact HL Metal – IPE Beam Offers & Technical Support

For detailed specifications, pricing and delivery options, contact our team or send your BOQ via our online form.

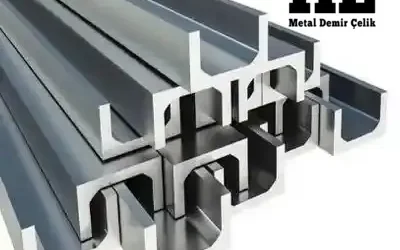

Contact HL Metal – Request IPE Beam QuotationUPE Steel Channel is part of the European standard EN 10365, which governs parallel flange channels. They are available in standardized sizes ranging from UPE 80 to UPE 400, and typically produced using structural steel grades such as S235JR, S275JR, and S355JR.

UPE Channel, also known as UPE Steel Channel or UPE Section, is a hot-rolled steel profile shaped like the letter “U” with parallel flanges. These channels are widely used in structural and mechanical engineering, offering an excellent strength-to-weight ratio and ease of installation.

Unlike traditional U-channels with tapered flanges (like UPN), the UPE Channel features parallel inner and outer flanges, which makes them ideal for applications requiring easy bolted or welded connections and consistent load distribution.

Key Features of UPE Channels

Parallel flanges: Ensures ease of connection and better load distribution

Hot-rolled manufacturing: Delivers high strength and durability

Standardized dimensions: Easy to integrate into structural designs

High resistance to bending and torsion

Available in various steel grades (EN 10025-2)

Common Applications

UPE Sections are used in a wide variety of industries and structural systems:

Steel frame construction (beams and purlins)

Machinery and equipment supports

Racking and shelving systems

Vehicle chassis and bodywork

Marine and offshore structures

Structural reinforcements in concrete works

Thanks to their high load capacity and dimensional consistency, UPE profiles are a go-to solution in modern engineering and construction projects.

UPE Channel vs UPN Channel

| Feature | UPE Channel | UPN Channel |

|---|---|---|

| Flange shape | Parallel | Tapered |

| Load distribution | Even, easier connections | Slightly less efficient |

| Standards | EN 10365 | DIN 1026-1 |

| Common usage | Modern steel structures | Traditional applications |

UPE Structural Channel Sizes

UPE steel channels are typically available in sizes from:

UPE 80 to UPE 400

Heights: 80 mm to 400 mm

Flange widths: 45 mm to 110 mm

Weights: 8 kg/m to over 50 kg/m

A full UPE weight chart and dimensional table can be provided by your steel supplier or engineering handbook.

Why Choose a UPE Steel Profile?

Efficient for horizontal or vertical load applications

Suitable for welding, bolting, and other connection types

Available in galvanized, primed, or painted finishes

Excellent for cost-effective steel frameworks

Whether you are designing a warehouse, assembling a machine, or building an offshore platform, UPE Structural Channels provide long-term strength and reliability.