- Ana Sayfa

- HEA Beam

HEA Beam

HEA Beam – Dimensions, Weights & Steel HEA Sections

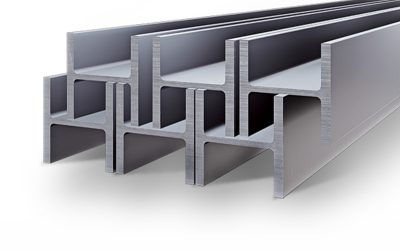

HEA beams (also called wide-flange beams or H-beams) are structural steel profiles with an H-shaped cross-section and parallel flanges. The “A” in HEA denotes a European wide-flange section with a relatively lighter profile compared to HEB or HEM beams, while still maintaining high load-bearing capacity and excellent structural performance.

Manufactured according to EN 10025 and related dimensional standards, HEA steel beams offer precise geometry, reliable mechanical properties and consistent quality. Their optimized design maximizes strength while minimizing weight, making them ideal for modern steel construction.

At HL Metal Demir Çelik Sanayi, we supply and export HEA beams with full traceability and processing options, helping engineers and fabricators build efficient, safe and economical structures.

HEA Beams: The Backbone of Modern Structural Engineering

HEA beams are fundamental components in steel construction and structural engineering. Known for their lightweight yet high-strength characteristics, HEA beams deliver optimal load-bearing capacity while maintaining structural efficiency.

For buildings, bridges and industrial facilities, choosing the right HEA beam section is essential for safe and cost-effective project execution. With a balanced flange-to-web ratio and standardized dimensions, HEA beams provide excellent performance in both bending and compression.

HEA Beams: Key Benefits

HEA beams offer several critical advantages over other structural elements:

- Superior strength-to-weight ratio: wide flanges and optimized cross-sections provide excellent load-bearing capacity without excessive weight, improving material efficiency and handling.

- Versatility: suitable for residential, commercial and industrial projects. HEA beams can be used as columns, primary beams, secondary beams, frameworks and reinforcements.

- Ease of fabrication: HEA beams can be cut, drilled, welded and bolted with standard fabrication methods, enabling flexible design solutions and fast assembly.

- Durability and longevity: produced from high-quality structural steels, HEA beams resist mechanical stress, deformation and – when coated or galvanized – environmental influences.

HEA Beam Dimensions & Weights

Below is a selection of common HEA beam sizes with nominal height, flange width, web thickness and theoretical weight per 12-meter length. Detailed tables and additional sizes are available on request.

| HEA Beam Type | Height H (mm) | Flange Width (mm) | Web Thickness (mm) | Weight (kg / 12 m) |

|---|---|---|---|---|

| HEA 100 | 96 | 100 | 5.00 | 202 |

| HEA 120 | 114 | 120 | 5.00 | 241 |

| HEA 140 | 133 | 140 | 5.50 | 299 |

| HEA 160 | 152 | 160 | 6.00 | 368 |

| HEA 180 | 171 | 180 | 6.00 | 430 |

| HEA 200 | 190 | 200 | 6.50 | 512 |

| HEA 220 | 210 | 220 | 7.00 | 611 |

| HEA 240 | 230 | 240 | 7.50 | 730 |

| HEA 260 | 250 | 260 | 7.50 | 825 |

| HEA 280 | 270 | 280 | 8.00 | 924 |

| HEA 300 | 290 | 300 | 8.50 | 1068 |

| HEA 320 | 310 | 300 | 9.00 | 1181 |

| HEA 340 | 330 | 300 | 9.50 | 1271 |

| HEA 360 | 350 | 300 | 10.00 | 1355 |

| HEA 400 | 390 | 300 | 11.00 | 1513 |

| HEA 450 | 440 | 300 | 11.50 | 1694 |

| HEA 500 | 490 | 300 | 12.00 | 1876 |

| HEA 550 | 540 | 300 | 12.50 | 2009 |

| HEA 600 | 590 | 300 | 13.00 | 2154 |

Theoretical weights are based on standard EN sections. For precise project calculations and additional HEA sizes, please request our full HEA / HEB / HEM beam tables or use the metal weight calculator on our website.

Common Applications of HEA Beams

HEA beams are widely used across multiple industries and structural applications:

- Construction: frames, columns, floors, roofs and bridge decks. HEA sections form the structural skeleton of many steel buildings, ensuring stability and strength.

- Industrial facilities: supporting heavy machinery, storage systems, mezzanine floors, cranes and platforms in factories and warehouses.

- Architectural design: exposed steelwork in modern architecture where open spaces, long spans and aesthetic steel details are desired.

- Infrastructure projects: bridges, tunnels, highway structures and railway systems requiring durable and long-lasting support.

HEA Beams: Technical Specifications

HEA beams are available in various sizes and material grades to suit different structural and design requirements. Key specifications include:

- Dimensions: widths typically from 100 mm upwards, with standardized heights (H), flange widths and web thicknesses for each HEA designation.

- Material grades: common structural steel grades such as S235, S275 and S355, according to project strength and ductility needs.

- Surface finish: supplied as black (mill finish), shop-primed or hot-dip galvanized to enhance corrosion resistance in harsh environments.

- Length: standard stock lengths typically 6 m and 12 m, with cut-to-length options according to drawings and site handling constraints.

- Standards: dimensional and material requirements according to EN standards and, where required, equivalent ASTM specifications.

Selecting the Right HEA Beam

Selecting the correct HEA beam for your project depends on several critical factors:

- Load requirements: determine design loads, spans and load combinations to choose the appropriate HEA size and steel grade.

- Design constraints: consider clearances, connection details, deflection limits and architectural requirements when selecting the beam section.

- Environmental conditions: for outdoor or corrosive environments, specify galvanized or coated HEA beams to extend service life.

- Compliance with standards: ensure that sections meet local and international codes, such as EN 10025 or equivalent ASTM standards.

When sending your BOQ or drawings, include beam designation (e.g. HEA 200, HEA 300), material grade, length, quantity and any processing requirements (cutting, drilling, coping, coating) so our team can prepare an optimized offer.

FAQ: HEA Beams & Steel Wide-Flange Sections

1) What is the difference between HEA, HEB and HEM beams?

All three are European wide-flange beams with similar shapes. Generally, HEA beams are lighter, HEB beams have medium weight and HEM beams are the heaviest sections for very high loads. The choice depends on design requirements and allowable deflections.

2) Can you supply HEA beams with processing?

Yes. We can supply HEA beams cut-to-length, drilled, coped, welded with plates and delivered with shop primer or galvanizing preparation, according to your fabrication drawings.

3) Do you provide mill test certificates?

Yes. Mill test certificates (EN 10204 3.1) and other documentation can be provided for each heat, including chemical composition and mechanical properties.

4) Can I combine HEA beams with other sections in one shipment?

Absolutely. Many projects combine HEA beams with HEB/HEM beams, IPE sections, UPN/UPE channels and hollow sections. We can consolidate them into a single, export-ready shipment.

Related Beam & Section Pages

Explore other structural steel sections that complement HEA beams in building frames and steel structures:

Need HEA Beams for Your Project? Get a Fast Quote

If you are looking for a reliable supplier of HEA beams, wide-flange steel beams and related structural sections, HL Metal Demir Çelik Sanayi is ready to support your next project with export-quality products and service.

With a proven track record, a comprehensive structural steel portfolio and strong focus on delivery performance, we help contractors, fabricators and EPC companies execute projects safely and efficiently.

📧 Contact HL Metal – HEA Beam Supply & Structural Steel Solutions

Contact us today and share your BOQ, beam schedule, grades, sizes and delivery terms. Our export team will prepare a competitive, optimized offer for HEA beams and companion sections such as HEB, HEM, IPE, UPN, UPE and rectangular hollow sections.

Contact HL Metal – Request an HEA Beam QuoteH-Shaped Beams: Engineered Strength for Modern Structures

H-shaped beams, also known as H-beams or wide flange beams, are essential structural steel components renowned for their exceptional load-bearing capacity, dimensional stability, and versatility. Characterized by their distinctive H-shaped cross-section, these beams provide superior strength-to-weight ratios compared to conventional profiles, making them a preferred choice in both large-scale and precision-engineered construction projects.

Manufactured from high-grade steel, H-shaped beams excel in distributing loads evenly across wide spans, minimizing bending, and enhancing overall structural integrity. They are widely used in applications such as bridges, high-rise buildings, industrial facilities, shipbuilding, and heavy machinery frameworks. Their broad flanges allow for easier connections and improved resistance to shear forces, offering engineers and architects design flexibility and performance reliability.

One of the key advantages of H-shaped beams is their efficiency in reducing material consumption without compromising structural strength. This translates into cost-effective solutions for demanding projects, where both durability and budget constraints are critical. Additionally, H-beams are available in various sizes, thicknesses, and steel grades, ensuring tailored solutions to meet specific project requirements.

For stakeholders seeking robust, efficient, and scalable steel solutions, H-shaped beams stand as an indispensable component, combining innovation, reliability, and long-term performance in modern construction landscapes.

.

Applications of H Shaped:

Construction: Used for frames in buildings, bridges, and warehouses.

Industrial Structures: Ideal for machinery supports and platforms.

Steel Fabrication: Commonly used in welded and bolted steel structures.

H Shape Material Grades:

S235JR (ST37)

S275JR (ST44)

S355JR (ST52)

H Shaped Characteristics:

H-shaped cross-section with wide and thin flanges

Lighter in weight compared to HEB and HEM beams, making them a more cost-effective solution for certain applications

Manufactured in accordance with EN 10365 and DIN 1025 standards

Available in sizes typically ranging from HEA 100 to HEA 1000, where the number represents the beam height in millimeters

Advantages and Features of H Shaped Beams

H shaped are widely recognized for their extensive use in the construction industry. Manufactured from structural steel, they are also commonly utilized in the construction of bridges and ships. As part of the structural profiles category, HEA Steel beam prices vary depending on their dimensions and weight, and detailed pricing is provided in the table below.

Ordering HEA Steel Beams

HEA beams are known for their high strength and load-bearing capacity. Prices vary based on the beam’s size and weight. You can select the most suitable dimensions for your project and purchase them with the assurance of HL Metal Demir Çelik Sanayi quality.

Although H shaped are typically manufactured according to standard dimensions, custom production is also available upon request. You can place an order by providing your required dimensions and weights. Standard products are listed in our HEA steel profile price table, and for custom orders, our sales representative will provide you with a tailored price quote.

Whether you choose from our range of standard HEA shaped or require a custom-fabricated solution, our customer support team is ready to assist you. In addition to fast delivery options, our wide product portfolio ensures that you can easily find what you’re looking for.

👉 Contact our sales team today for detailed information and to place your order for HEA steel profile.

1. Construction and Structural Profiles

This category includes materials and structural components commonly used in the construction industry. These profiles are formed by processing materials such as steel, concrete, and wood into specific shapes and dimensions. They play a critical role in ensuring the fundamental strength and safety of buildings.

Steel Structural Profiles

- I-Beam (I Profile): A widely used profile for steel beams and columns.

- Square and Rectangular Profiles: Used in structural applications such as columns, beams, and support members in the form of steel tubes or box sections.

- U-Channel Profiles: Commonly used in wall panels, floor decking, and various support elements.

- L-Beam (Angle Profile): Utilized for creating corner joints in various structural components.

Concrete and Prefabricated Structural Profiles

- Reinforced Concrete Beams and Columns: Load-bearing elements cast in special molds and used in structural frameworks.

- Prefabricated Concrete Elements: Factory-made components that are assembled on-site, often preferred in fast-track construction projects.

2. Mechanical Structural Profiles

These profiles define the structural features of machinery and mechanical components. Profiles used in industrial machinery are typically made from high-strength ma