- Ana Sayfa

- Galvanized Steel Sheet

Galvanized Steel Sheet

Galvanized Steel Sheet & Coil – DX51D+Z Hot Dip Galvanized Sheet & GI Sheet Supplier

Galvanized steel sheet – also known as galvanized sheet, GI sheet, HDG steel sheet or zinc coated steel sheet – is a cold or hot rolled steel substrate coated with a protective zinc layer. This zinc layer provides outstanding corrosion resistance properties, making galvanized metal sheet the preferred choice for roofing, cladding, HVAC systems, ducting, fencing, agricultural buildings and a wide range of industrial applications.

HL Metal supplies hot dip galvanized steel sheet and galvanized steel sheet coil in accordance with EN 10346 DX51D and similar grades, with coating classes from Z100 to Z275. Whether you need 1 mm galvanized sheet, 0.5 mm galvanized sheet or heavy-gauge HDG sheet, we offer a comprehensive galvanized steel sheet and coil range with competitive galvanized steel sheet price per ton and per square metre.

As an export-oriented galvanized steel sheet supplier and GI sheet & coil DX51D Z275 stockist, HL Metal supports roofing contractors, HVAC manufacturers, ducting and ventilation fabricators, fence producers and steel distributors in multiple markets.

Key Specifications at a Glance

- Product types: galvanized steel sheet, galvanized steel coil, GI sheet & coil

- Standards: EN 10346 DX51D+Z, other galvanized sheet technical specifications on request

- Coating mass: hot dip galvanized steel sheet Z100–Z275 (and special coatings on demand)

- Typical thickness: 0.40–3.00 mm (0.5 mm and 1 mm galvanized sheet as standard)

- Stock sheet sizes: 1000×2000 / 1250×2500 mm galvanized sheet stock sizes

- Surface: regular spangle or minimized spangle, skin-passed or non-skin-passed, oiled or dry

- Forms: galvanized sheet, galvanized sheet roll, slit coil, narrow strip

- Applications: roofing & construction, HVAC and ducting, fencing, fabrication, agricultural buildings

What Is Galvanized Steel Sheet?

Galvanized steel sheet is a flat carbon steel product that has been coated with a layer of zinc by the hot dip galvanizing process. The zinc coating adheres metallurgically to the base metal, creating a durable and continuous barrier against corrosion. In everyday language, galvanized steel sheet is frequently referred to as GI sheet, galvanized iron sheet, galvanized sheet metal or simply zinc galvanized sheet.

In coil form it is known as galvanized steel sheet coil or DX51D galvanized sheet coil, which can be slit, cut-to-length or roll-formed into roofing, cladding, ducts and various fabricated components.

Standards and Technical Specifications – EN 10346 DX51D+Z

HL Metal typically supplies galvanized steel sheet EN 10346 DX51D and related grades, which are designed for forming and profiling. The galvanized sheet technical specifications EN 10346 define steel grades, zinc coating masses, mechanical properties and test conditions.

- Standard: EN 10346 – Continuously hot-dip coated steel flat products

- Grade: DX51D – general use, suitable for bending and profiling

- Coating: DX51D+Z100 to DX51D+Z275 (GI sheet & coil DX51D Z275 on request)

- Typical yield strength: approx. 140–300 MPa (depending on thickness and condition)

- Typical tensile strength: approx. 270–500 MPa

- Condition: As-coated, skin-passed, oiled or passivated depending on application

For specific forming, stamping or deep-drawing applications, alternative grades under EN 10346 can be supplied upon request, always supported with mill test certificates.

Galvanized Sheet Dimensions, Thickness and Weight Chart

HL Metal maintains a wide range of galvanized sheet stock sizes 1000×2000 / 1250×2500 mm for immediate delivery. Other dimensions, including 1500×3000 mm or custom cut-to-length sheets, are available depending on volume. The theoretical galvanized steel sheet weight chart below is based on the density of carbon steel; the additional zinc layer has a relatively small effect on total weight.

| Dimensions (mm) | Thickness (mm) | Approx. Weight per Sheet (kg) |

|---|---|---|

| 1000 × 2000 | 0.50 | ≈ 7.85 |

| 1000 × 2000 | 0.80 | ≈ 12.6 |

| 1000 × 2000 | 1.00 | ≈ 15.7 |

| 1250 × 2500 | 0.50 | ≈ 12.3 |

| 1250 × 2500 | 0.80 | ≈ 19.7 |

| 1250 × 2500 | 1.00 | ≈ 24.6 |

| 1250 × 2500 | 1.50 | ≈ 36.9 |

| 1250 × 2500 | 2.00 | ≈ 49.2 |

| 1500 × 3000 | 1.50 | ≈ 52.9 |

| 1500 × 3000 | 2.00 | ≈ 70,65 |

| 1500 × 3000 | 3.00 | ≈ 105,97 |

| 1500 × 3000 | 4.00 | ≈ 141,3 |

Values are indicative and calculated with a density of 7.85 g/cm³. For precise weights and custom coil widths, you can use our galvanized steel sheet weight chart & calculator .

Zinc Coatings Z100–Z275 and Corrosion Resistance Properties

The protective performance of a zinc galvanized sheet primarily depends on the coating mass. HL Metal supplies hot dip galvanized steel sheet Z100–Z275, carefully selected according to the environment and service life expectations.

- Z100 / Z140: lighter coatings for interior use, HVAC, ducting and dry environments

- Z200 / Z225: balanced protection for standard outdoor and roofing applications

- Z275 galvanized steel sheet: enhanced coating mass for demanding outdoor durability

Thanks to the sacrificial behaviour of zinc, galvanized steel sheet corrosion resistance properties remain effective even if small areas of the coating are damaged during cutting or forming. For particularly aggressive atmospheres, galvanized steel sheet can also be post-painted to form a duplex system, combining barrier and sacrificial protection.

Galvanized Steel Sheet for Roofing and Construction

Galvanized steel sheet for roofing and construction is a long-established solution in residential, commercial and industrial buildings. GI sheet metal is easy to profile, offering lightweight yet strong roofing and cladding systems with excellent water shedding and weather protection.

- Corrugated and trapezoidal hot dip galvanized sheet for construction

- Roofing and wall cladding for warehouses, workshops and agricultural buildings

- Gutters, flashings, ridge caps and accessory parts in galvanized sheet

- Structural decking and secondary framing elements in GI sheet metal

For projects requiring additional insulation and thermal performance, galvanized steel sheet can be combined with sandwich panels or insulated roofing systems, providing both structural strength and long-term durability.

Galvanized Steel Sheet for HVAC Systems and Industrial Applications

Due to its clean surface, formability and corrosion protection, galvanized steel sheet for HVAC systems has become the industry standard for ductwork, ventilation and air distribution components. Galvanized sheet for ducting and ventilation ensures low air leakage, hygienic surfaces and long service life in commercial buildings, hospitals and industrial facilities.

- Rectangular and round ducts, plenums and air handling components

- Fan casings, filter housings and air distribution boxes

- Galvanized sheet for fencing and fabrication of frames, gates and security enclosures

- Galvanized sheet for agricultural buildings, animal shelters and storage units

In general, galvanized steel sheet for industrial applications is used for cabinets, machine guards, electrical enclosures, conveyor covers and countless fabricated parts where corrosion protection and cost-efficiency are important.

Galvanized Steel Sheet vs Cold Rolled Steel Sheet

While cold rolled steel sheet offers a very smooth surface and tight dimensional tolerances, it lacks built-in corrosion protection. Galvanized steel sheet vs cold rolled steel sheet can be summarized as follows:

- Cold rolled steel sheet: excellent surface finish and formability, but requires subsequent painting or coating for corrosion resistance.

- Galvanized steel sheet: slightly less perfect surface but incorporates a zinc coating that protects both bare edges and damaged areas through sacrificial action, reducing maintenance costs.

In many projects, the ideal solution is a combination: cold rolled as a base material in selected areas, and DX51D+Z galvanized steel sheet and plate where long-term corrosion protection is essential.

Galvanized Steel Sheet Price, Per Ton and Per Square Metre

Galvanized steel sheet price is influenced by the same core factors as other steel products: global steel and zinc markets, coating mass, thickness, coil width, order size and logistics. HL Metal offers competitive galvanized steel sheet price per ton for bulk coils and a transparent galvanized sheet metal price list for regular customers and distributors.

For roofing, cladding and ducting projects, contractors often compare cost on an area basis. We therefore provide galvanized sheet per square meter price on request, taking into account the specific thickness (for example 0.5 mm galvanized sheet vs 1 mm galvanized sheet), coating mass and final destination.

Galvanized Steel Sheet and Coil Supplier – Why HL Metal?

As a trusted galvanized steel sheet supplier and galvanized sheet factory partner, HL Metal focuses on reliable quality, flexible logistics and responsive customer service. We work closely with mills and coating lines to deliver DX51D galvanized sheet coil manufacturer capabilities directly to your project.

- Wide range of galvanized steel sheet and coil in DX51D+Z100–Z275

- Standard galvanized sheet stock sizes 1000×2000 / 1250×2500 and custom cut-to-length sheets

- GI sheet & coil DX51D Z275 for enhanced outdoor durability

- Optional slitting, blanking and profiling through our service center

- Export packing, documentation and multi-product loads with HR, CR and galvanized sheet

Combined loads including hot rolled steel sheet, cold rolled steel sheet , hot rolled pickled steel sheet (HRP) and galvanized steel sheet can be arranged to optimize freight costs.

Request Your Galvanized Steel Sheet & Coil Offer

Whether you are looking for galvanized steel sheet for roofing and construction, galvanized steel sheet for HVAC systems, or galvanized sheet for fencing and fabrication, HL Metal is ready to support your project with technical guidance and competitive pricing.

Send us your required thickness, dimensions, coating class (for example Z275 galvanized sheet for outdoor durability), quantity and destination. Our team will prepare a tailored quotation including the most efficient combination of sheets and coils.

Galvanized Steel Sheet / Plate – Global Grade Equivalence Table

The following chart gives approximate global grade equivalences for galvanized steel sheet and plate according to EN 10346, ASTM A653, JIS G3302 and common GOST grades. These are for general guidance only – final selection must always be based on the latest standards, chemical composition and mechanical properties declared on mill certificates.

| EN / European Grade (EN 10346) | Typical Coating & Use | USA (ASTM A653) | Japan (JIS G3302) | Russia / CIS (GOST)* | Notes |

|---|---|---|---|---|---|

| DX51D+Z EN 10346 | Z100–Z275 hot dip galvanized sheet / coil. General forming and profiling applications. | ASTM A653 CS Type A/B/C (Commercial Steel, galvanized) | JIS SGCC (Commercial quality GI sheet) | Approx. to GOST 14918 commercial grades (e.g. 08ps, 08yu, 08kp with zinc coating) | Standard GI sheet for roofing, cladding, HVAC ducts and light fabrication. Good formability, moderate strength. |

| DX52D+Z EN 10346 | Z140–Z275, improved formability for bending and light drawing. Used for more demanding profiles and panels. | ASTM A653 FS Type A/B (Forming Steel) | JIS SGCD1 / SGCD2 (Drawing quality GI) | Approx. to drawing-quality GOST 14918 grades (e.g. 08kp with specified ductility) | Better elongation than DX51D+Z. Suitable for roll-formed sections, gutters and deeper bends. |

| DX53D+Z EN 10346 | Z140–Z275 deep drawing GI sheet for complex shapes. Used where high ductility is required. | ASTM A653 DDS (Deep Drawing Steel) | JIS SGCD3 (Deep drawing quality GI) | Approx. to deep-drawing quality GOST 14918 galvanized grades | Optimised for deep-drawn components, housings and complex pressings with tight radii. |

| DX54D+Z EN 10346 | Very high formability, Z coatings for demanding deep-drawing applications. | ASTM A653 EDDS (Extra Deep Drawing Steel) | JIS SGCD4 (Extra deep drawing GI) | Approx. to extra-deep-drawing galvanized grades in GOST 14918 | Used where extreme drawability and surface quality are critical – complex stampings, appliance parts. |

| S220GD+Z / S250GD+Z EN 10346 | Structural galvanized grades with min. yield 220–250 MPa. Typically Z140–Z275 for construction. | Approx. to ASTM A653 SS Grade 33 (Structural Steel, galvanized) | JIS SGC340 (and nearby strength levels) | Approx. to GOST 14918 structural classes (e.g. 220, 250 with zinc coating) | Used in light-gauge structural members, purlins, light framing, roofing and cladding profiles. |

| S280GD+Z EN 10346 | Structural GI with min. yield ≈ 280 MPa. Often Z200–Z275 for outdoor durability. | Approx. to ASTM A653 SS Grade 37 or similar structural classes | JIS SGC400 | Approx. to GOST 14918 280 MPa class galvanized structural steels | Used in higher-strength roofing profiles, structural decking, cold-formed sections and trusses. |

| S320GD+Z / S350GD+Z EN 10346 | High-strength structural GI (min. yield ≈ 320–350 MPa). Z200–Z275 for exposed structural members. | Approx. to ASTM A653 SS Grade 40 / 50 (depending on exact yield strength) | JIS SGC440 / SGC490 range | Approx. to high-strength galvanized structural steels in GOST 14918 | Preferred in load-bearing cold-formed profiles, purlins, channels and high-strength framing systems. |

| DX / SxxxGD Series (general overview) | DX = forming grades (DX51D–DX54D). SxxxGD = structural galvanized grades. | ASTM A653 CS / FS / DDS / EDDS / SS series | JIS G3302 SGCC / SGCD / SGC series | GOST 14918 Commercial, deep-drawing and structural classes | This row summarizes how EN galvanized steel sheet & plate grades map to other international systems. Always compare exact mechanical values and coating requirements. |

* GOST equivalents are indicative only. For critical engineering projects, always verify with the latest EN 10346, ASTM A653, JIS G3302 and GOST standards, and confirm compatibility through detailed chemical and mechanical comparison of the specific heats and coating classes supplied.

Value-Added Processing & Surface Protection for Hot Rolled Steel

Turn your hot rolled steel sheets and plates into finished, ready-to-assemble components. HL Metal combines advanced cutting, forming and protective coating services to support your fabrication process from raw material to final part.

CNC Laser Cutting

Achieve clean edges, tight tolerances and complex geometries with our CNC laser cutting service. From thin-gauge sheet metal to structural plate, our high-performance laser systems deliver precision parts with minimal burrs and reduced finishing work.

CNC Plasma Cutting

For thicker plates and heavy-duty sections, our CNC plasma cutting provides robust and economical cutting performance. Ideal for structural fabrication, machinery frames and industrial steelwork where productivity and reliability are key.

Laser Cutting for Tube & Hollow Section

Customise circular, square and rectangular hollow sections with high-precision laser cutting. We produce slots, holes, mitre cuts and complex contours directly on tubes and hollow sections, reducing welding time and simplifying assembly for structural and architectural projects.

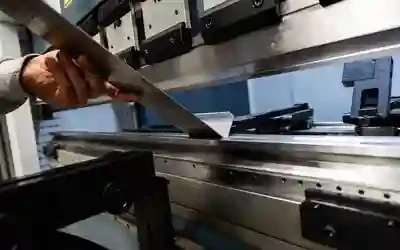

Press Brake Bending

Transform flat hot rolled steel sheets into channels, brackets and complex profiles with our CNC press brake bending. High-tonnage, multi-axis machines ensure consistent angles, repeatable bends and accurate parts ready for welding or bolting.

Sandblasting, Coating & Shop Primer

Prepare your steel surfaces for long-term performance with professional sandblasting, coating and shop primer application. We remove mill scale and rust, create a controlled surface profile and apply shop primer systems that protect your plates and profiles during fabrication, transport and installation.

Cut-to-Length from Coil

Optimise your supply chain with cut-to-length from coil. We uncoil, level and cut hot rolled, cold rolled and galvanized coils into precise sheet lengths, helping you reduce on-site cutting, handling time and scrap while keeping sheet flatness under tight control.

Discuss Your Project with HL Metal

Need a combined package of hot rolled steel sheet and plate with cutting, bending, blasting, coating or cut-to-length from coil? Share your drawings, material grades and delivery terms — our team will prepare a tailored proposal for your project.

ÜRÜN TANIMLARI | |

HR | Hot Rolled Coil, Sıcak Haddelenmiş Sac |

HRP | Hot Rolled Pickled Coil, Sıcak Haddelenmiş Asitle Temizlenmiş Sac |

CRF | Cold Rolled Full Hard, Soğuk Haddelenmiş Sac |

CR | Cold Rolled Coil, Soğuk Haddelenmiş Tavlanmış Sac |

GI | Sürekli Sıcak Daldırma ile Galvaniz Kaplanmış Soğuk Sac |

GL | Sürekli Sıcak Daldırma ile Galvalume Kaplanmış Soğuk Sac |

PPGI | Boya ile Sürekli Kaplanmış Galvanizli Yassı Çelik |

PPGL | Boya ile Sürekli Kaplanmış Galvalume Yassı Çelik |

Applications of Galvanized Steel Sheet

Construction: Roof panels, wall coverings, studs, ductwork

Automotive: Car frames, chassis, underbody parts

Agricultural: Grain silos, barn roofing, fencing

HVAC: Ventilation ducts, air handling units

Electrical: Enclosures, switch boxes

Its versatility and cost-effectiveness make it a go-to choice in modern industry.

Surface Finishes & Coating Options

We offer galvanized steel sheets with:

Regular spangle (visible zinc pattern)

Minimized spangle (uniform, clean finish)

Zero spangle (smooth for paintability)

Coating thicknesses: Z100, Z275, Z450, etc. (based on customer needs)

Additional options:

Oiled or dry finish

Chromated or non-chromated coating

Skin-passed or non-skin-passed surfaces

Custom Cutting & Fabrication Services

At HL Metal Iron & Steel, we provide cut-to-length, slitting, shearing, and hole punching services to match your specifications. Whether you need standard dimensions or custom shapes, our team ensures fast and accurate delivery.

Galvanized Sheet — Product Introduction & Technical Sales Guide

This page is part of our product cluster: /products/galvanized-sheets. For full certification and raw material traceability see Technical Data. To request a tailored quote use the Request Quotation button.

Overview

Galvanized Steel Sheet is a zinc-coated carbon steel product designed to resist corrosion while remaining economical and easy to fabricate. Our portfolio includes Galvanized Sheet Metal, Galvanized Steel Plate, Hot-Dip Galvanized Sheet and Cold Rolled Galvanized Sheet variants supplied as Galvanized Steel Coil and Galvanized Steel Roll, or cut-to-length sheets.

Why choose galvanized steel?

- Cost-effective corrosion resistance compared to stainless alternatives.

- Proven performance across roofing, automotive and industrial sectors.

- Available in a wide range of coating weights and base steel grades.

Technical Specifications

This section summarises common specifications. All specific mechanical properties, chemical analysis and certification files are available on our Technical Data page.

| Product | Base Steel / Standard | Thickness (mm) | Zinc Coating (g/m²) | Forms |

|---|---|---|---|---|

| DX51D Galvanized Sheet | EN 10346 | 0.30 — 3.00 | Z275 Galvanized Steel range Z80 — Z275 | Galvanized Steel Coil, Cut-to-Length, Sheets |

| S350GD Galvanized Sheet | EN 10346 / EN 10149 | 1.00 — 4.00 | Z120 — Z275 | Plate, Blanks |

| Electro-galvanized Sheet | ASTM / JIS | 0.30 — 1.50 | EG Coating 10 — 60 (approx.) | Panel, Strip |

Galvanized Steel Sheet Thickness & Tolerances

We offer a broad thickness range. Standard tolerances apply; custom tolerances can be specified for high-precision orders. Refer to tolerances for details.

Galvanized Sheet Sizes & Coil Data

Common coil widths and cut lengths are available. Our production can supply bespoke widths for roll-formers and panel lines. See the Cutting Services page for slitting and cut-to-length options.

Galvanized Sheet Weight Chart

A weight chart is useful for logistics and cost calculations — downloadable from Resources. Weight is calculated by base steel thickness and density; coating adds marginal mass depending on g/m².

Applications & Use Cases

Our products serve diverse industries. Typical applications include:

- Galvanized Sheet for Roofing and cladding systems where long-term corrosion protection is required.

- Galvanized Sheet for Construction — structural and secondary elements.

- Galvanized Sheet for Automotive — inner panels, reinforcements and components benefitting from economical corrosion protection.

- Galvanized Sheet for Fencing and security barriers.

- Galvanized Sheet for HVAC ducting and enclosures.

- Galvanized Sheet for Industrial Applications such as agricultural machinery and outdoor equipment.

Coating Selection Guidance

For indoor, low-corrosivity environments, a lighter coating like Z80 may be sufficient. For coastal or aggressive industrial atmospheres choose Z275 or apply protective paint systems. See Coating Guidance for practical selection matrices.

Sourcing, Pricing & Commercial Terms

We act as both Galvanized Sheet Supplier and manufacturer via our network, offering competitive terms for OEMs and distributors. Typical commercial touchpoints:

- Galvanized Sheet Price is driven by steel raw material costs, coating weight, order quantity and delivery Incoterms.

- Pricing can be quoted per unit area or weight (see Galvanized Sheet Price per Kg and Galvanized Sheet Price per Ton).

- We provide volume discounts for Wholesale Galvanized Sheet purchases and contract pricing for repeat buyers.

Request a commercial proposal at Request Quotation or view our standard commercial terms on the Terms & Conditions page.

Distribution & Export

We support international shipments and customs documentation for buyers. If you are looking to Buy Galvanized Sheet Online for small quantities, visit our Online Store. For large projects contact our export desk at /contact#export. We are a trusted Galvanized Sheet Manufacturer and Galvanized Steel Sheet Exporter for multiple markets.

Ordering, Delivery & After-Sales

Ordering process and logistics options are designed to be transparent:

- Submit specification or sample request via /contact.

- Receive proforma including Galvanized Sheet Price per Ton and estimated lead-time.

- Confirm order — choose EXW, FOB or CIF delivery terms.

- Production, quality inspection and shipment are managed with traceable lot numbers; certificates are issued per shipment.

Cutting & Value-Added Services

Available services: slitting, cut-to-length, edge conditioning, pre-painting, and packaging for project sites. See Services for full capabilities.

FAQ

What is Galvanized Sheet?

Galvanized Steel Sheet is steel sheet coated with zinc to protect against corrosion. The coating method (hot-dip vs electro-galvanized) affects thickness and performance.

Galvanized Steel Sheet vs Stainless Steel Sheet — which to choose?

Choose galvanized when cost-effective corrosion protection is needed and stainless when higher corrosion resistance, aesthetic or non-magnetic properties are essential. We can advise based on application and life-cycle cost.

How do I find the Best Galvanized Steel Sheet for Outdoor Use?

Consider coating weight (Z275 or higher for coastal use), post-treatment (paint, passivation) and expected lifetime. Our technical team can propose an optimized specification.

Is there a Durable Galvanized Steel Sheet for Industrial Use?

Yes — structural grades like S350GD Galvanized Sheet with heavier zinc coatings provide robust performance for industrial environments. Consult Case Studies for examples.

Maintenance and Longevity — Maintenance-Free Galvanized Steel Sheet?

No metal is entirely maintenance-free, but properly specified and coated Galvanized Steel Sheet with correct detailing and protective finishes can provide decades of low-maintenance service.

Contact & Support

For quotations, technical files and export enquiries, contact our sales team or visit the relevant pages:

- Contact Form & Quote

- Full Technical Data & Certificates

- Company & Manufacturing Info

- Engineering Support

If you need a quick price check, share your required thickness, coil width, coating weight (g/m²) and quantity (tons) — we’ll respond with a market-aligned quote.

Advanced Steel Tubes & Hollow Sections Overview

Our steel tubes and hollow sections (rectangular, square, and circular) provide unmatched strength, precision, and reliability for construction, industrial, and structural applications. Manufactured from high-quality S235, S275, and S355 steel grades, our products comply with international standards such as EN 10219-2:2019 and EN 10210. Each steel tubeand box profile undergoes rigorous quality inspections to ensure dimensional accuracy, mechanical strength, and corrosion resistance.

These solutions are ideal for structural frameworks, mechanical components, automotive applications, and industrial machinery. With custom sizing, cut-to-length options, and surface treatments including galvanization, clients can optimize both performance and longevity.

As a trusted steel tube supplier and box profile manufacturer, we offer competitive pricing, bulk availability, and worldwide delivery. Request our technical datasheets and quotations to access high-performance, durable, and reliable hollow sections and steel tubes engineered for modern construction and industrial projects.