- Ana Sayfa

- Support Sheet

Support Sheet

Support Sheet & Reinforcement Sheet for uPVC Windows and Doors

Support Sheets and Reinforcement Sheets are critical structural inserts used inside uPVC and PVC window and door profiles to enhance dimensional stability, tensile strength and long-term resistance against bending, twisting and warping. Whether in residential windows or industrial-grade uPVC doors, a properly engineered Steel Reinforcement Sheet or PVC Support Sheet is essential for mechanical performance and compliance with international safety standards.

HL Metal specialises in high-quality PVC Reinforcement Sheets, Galvanized Support Sheets, Steel Reinforcement Sheets and Custom Size Reinforcement Sheets designed for modern extrusion lines, profile producers and window system manufacturers worldwide.

- What Is a Support Sheet / Reinforcement Sheet?

- Product Types & Main Variants

- Technical Specification & Tolerances

- Advanced Engineering & Performance

- Performance in uPVC Window & Door Systems

- Online Availability, Pricing & Export Service

- Industrial Applications & Benefits

- Why Choose HL Metal as Your Support Sheet Supplier?

What Is a Support Sheet / Reinforcement Sheet?

A Support Sheet – also known as Reinforcement Sheet, PVC Reinforcement Sheet, Steel Insert for uPVC Profiles or Internal Reinforcement Sheet – is a metal strip placed inside the reinforcement chamber of PVC window and door profiles. It increases:

- Bending resistance and stiffness

- Screw-holding capacity for hinges, locks and fittings

- Dimensional stability under thermal expansion

- Load-bearing capacity under glass and wind loads

- Overall lifespan of uPVC and PVC frame systems

These inserts are typically manufactured from galvanized steel, cold-rolled mild steel or hot-dip galvanized steel, in compliance with EN and ASTM standards. HL Metal offers multiple geometries (U, C, L, Z, omega and flat designs) to match your profile chambers.

Product Types & Main Variants

PVC Reinforcement Sheet

Our PVC Reinforcement Sheet – also referred to as PVC Profile Reinforcement Sheet or PVC Frame Support Sheet – is optimised for:

- uPVC window sash and frame reinforcement

- Multi-chamber profile designs

- High-speed extrusion line compatibility

The smooth, PVC-compatible surface ensures easy insertion without damaging internal chambers or seals.

Galvanized Support Sheet

Galvanized Support Sheet (Z100–Z275) combines structural strength with corrosion resistance. It is ideal for:

- Outdoor window and door systems

- Coastal or humid environments

- Coloured and laminated PVC profiles

Steel Reinforcement Sheet

The Steel Reinforcement Sheet is designed for heavy-duty, load-bearing applications such as:

- uPVC entrance doors and sliding doors

- Large, heavy glazing elements

- Reinforced mullion and transom profiles

Support Sheet for PVC Windows & Doors

Our Support Sheet For PVC Windows and Reinforcement Sheet For UPVC Doors enhance:

- Alignment and geometry of sash and frame

- Wind load performance in high-rise buildings

- Long-term resistance to sagging and deformation

Custom Size Reinforcement Sheet

HL Metal manufactures Custom Size Reinforcement Sheets with precise thickness, width and length, including:

- Special hole patterns for screws and hardware

- Embossed or stamped shapes for better interlock

- PVC-compatible surface treatments and optional RAL paint

Technical Specification & Tolerances

Our PVC Support Sheet, Galvanized Support Sheet and Steel Reinforcement Sheet are produced using certified steel grades and controlled processes in line with EN and ASTM norms.

Material Composition

| Component | Specification |

|---|---|

| Base Material | Mild Steel – EN 10346 / EN 10130 / ASTM A653 (DC01–DC04) |

| Coating Type | Hot-Dip Galvanized (Z100–Z275), optional electrogalvanized |

| Coating Thickness | Approx. 7–20 μm per side (depending on zinc grade) |

| Surface Finish | Degreased / Oiled / Dry / PVC-compatible surface |

| Optional Paint Coating | Custom RAL colours available on request (internal use) |

Dimensional Tolerances

| Parameter | Standard Tolerance |

|---|---|

| Sheet Thickness | 0.50 mm – 2.00 mm (± 0.05 mm) |

| Width | 15 mm – 120 mm (± 0.3 mm) |

| Length | 2,500 mm – 6,000 mm (± 1.5 mm) |

| Flatness | ≤ 2 mm deviation per meter |

| Perpendicularity | ≤ 1 mm per meter |

Custom sizes, special shapes and alternative steel grades are available upon request for OEM and system house projects.

Advanced Engineering & Performance

HL Metal’s Metal Support Sheet For PVC is engineered for extrusion lines that demand high repeatability and low scrap rates. Each Profile Reinforcement Sheet is checked for thickness, coating integrity and surface smoothness to guarantee 100% compatibility with uPVC extrusion standards.

- Increased resistance to bending and deflection

- Improved screw anchorage for hinges, locks and brackets

- Enhanced fire resistance when used with fire-rated PVC systems

- Reduced thermal expansion in long profile lengths

- Compatible with automation and robotic assembly

- Optimised for high-speed Support Sheet For Extrusion Process

Performance in uPVC Window & Door Systems

In uPVC systems, our Reinforcement Sheet For UPVC Doors and Support Sheet For PVC Windows are designed to:

- Reinforce door sashes, frames and mullions

- Carry glazing weights and wind pressure safely

- Maintain alignment and prevent sash drop over time

- Work seamlessly with multi-chamber profile designs

Products such as PVC Profile Steel Insert, PVC Frame Support Sheet, Window Reinforcement Steel and Internal Reinforcement Sheet can be adapted to your profile series and tooling design.

Online Availability, Pricing & Export Service

Looking to Buy PVC Reinforcement Sheet Online or source a Support Sheet Supplier for multiple markets? HL Metal offers:

- Technical datasheets and product catalogues for system designers

- Competitive PVC Support Sheet Prices based on steel grade, zinc coating and dimensions

- Volume discounts for large-scale extrusion and window factories

- Export-ready packaging and documentation for over 20 countries

- ISO 9001:2015-certified manufacturing and full mill certificates

Industrial Applications & Benefits

Our Support Sheet and Reinforcement Sheet range is used across various industries:

- uPVC window and door manufacturing

- Plastic profile extrusion factories

- Curtain wall and façade systems

- Roller shutter and cover systems

- Electrical and telecommunication profile reinforcement

Whether you need a Structural Support Sheet for curtain walls or a Profile Reinforcement Sheet for high-performance doors, HL Metal delivers high-strength reinforcement sheet solutions with proven mechanical benefits.

Why Choose HL Metal as Your Support Sheet Supplier?

HL Metal is recognised as a reliable Reinforcement Sheet Manufacturer and Support Sheet Factory Export partner, combining:

- Consistent quality and tight tolerances

- Flexible Custom Support Sheet Production

- Fast lead times and container-based logistics

- Strong technical support for profile designers and system houses

Request a Tailored Support Sheet & Reinforcement Sheet Offer

Share your profile drawings, required steel grades, zinc coating class, dimensions and annual volumes. HL Metal will prepare a customised quotation for PVC Reinforcement Sheets, Galvanized Support Sheets, Steel Reinforcement Inserts and Custom Size Reinforcement Sheets tailored to your uPVC window and door systems.

Hollow Sections & Structural Profiles

HL Metal supplies a complete range of square and rectangular hollow sections, galvanized and painted hollow sections, special shaped profiles and light gauge steel structural profiles for industrial fabrication, steel construction and architectural applications.

Square Hollow Sections

Precision-formed square hollow sections (SHS) for steel structures, machinery frames, fencing and general fabrication. Available in multiple wall thicknesses, lengths and grades for both welded and bolted connections.

Rectangular Hollow Sections

High-strength rectangular hollow sections (RHS) designed for beams, columns, platforms and architectural steelwork. Excellent load-bearing performance with clean, modern aesthetics for visible structures.

Galvanized Hollow Sections

Hot-dip galvanized hollow sections for outdoor and corrosive environments. Ideal for fencing systems, façade substructures, agricultural buildings and industrial plants requiring long-term corrosion protection.

Painted Hollow Sections

Factory primed and painted hollow sections that reduce on-site coating work and speed up installation. Suitable for projects where aesthetic finish, brand colour and additional surface protection are required.

Special Shaped Profiles

Custom special shaped profiles tailored to your drawings and technical requirements. Optimise weight, performance and assembly by using profiles engineered specifically for your façade systems, framing details or machinery designs.

Light Gauge Steel Structural Profiles

Cold-formed light gauge steel structural profiles for lightweight framing, modular buildings, secondary structures and drywall systems. Designed for high strength-to-weight ratio and fast installation on site.

Request a Hollow Sections & Profiles Offer

Share your required dimensions, steel grades, surface treatments and annual quantities. HL Metal will prepare a tailored proposal for square and rectangular hollow sections, galvanized and painted hollow sections, special shaped profiles and light gauge steel structural profiles with competitive lead times and export-ready packaging.

Galvanized steel plates are coated with zinc to prevent corrosion, which is commonly seen in metals. The galvanized material can be applied effectively to almost any wet or humid surface, making it a preferred choice in such environments. Today, galvanized steel plates are widely used on moist and damp floors due to their high protective performance.

The main component of galvanized plates, zinc, provides a strong barrier against various negative environmental effects, preventing these from damaging the surface of the sheet metal. As a result, galvanized plates help extend the durability and integrity of metal structures and components.

Galvanized steel plates are commonly used across many industrial sectors because of their ease of use and practical advantages. They are especially preferred in manufacturing processes to increase the resistance and longevity of the final products.

In iron and steel production, wet surfaces pose a significant problem. Galvanization helps eliminate this issue by protecting the metal from moisture-induced damage, especially rust and corrosion. This is why galvanized sheets are widely used in the production of goods that are exposed to moisture or humidity.

At HL Metal Iron & Steel, we offer top-quality and competitively priced galvanized steel plates to meet your business needs. Our expert team is ready to assist you with detailed information and personalized product solutions.

Premium Quality Galvanized Steel Products for Industrial Applications

Galvanized steel is one of the most widely used materials in modern construction, infrastructure, and manufacturing industries due to its exceptional corrosion resistance, durability, and cost-effectiveness. At HL Metal, we offer a broad range of galvanized products, including sheets, coils, tubes, and profiles designed to meet the diverse needs of our clients across Europe, the Middle East, and North Africa.

What is Galvanized Steel?

Galvanized steel refers to steel that has been coated with a layer of zinc to protect it from corrosion. The most common process is hot-dip galvanization, where the steel is submerged in molten zinc, creating a strong and uniform protective layer. This zinc barrier significantly extends the product’s service life, especially in harsh outdoor environments.

Our Galvanized Product Range

We supply a wide variety of galvanized items, such as:

Galvanized Sheets (plain, patterned, or corrugated)

Galvanized Structural Profiles (angles, channels, hollow sections)

Cold-Formed Galvanized Profiles for construction and framing systems

Each product is available in various thicknesses, widths, and zinc coating levels (Z100 – Z275), tailored to your project requirements.

Key Advantages

Excellent Corrosion Resistance: Ideal for humid, coastal, and industrial environments

Low Maintenance Costs: Extended lifespan with minimal upkeep

Weldable and Paintable: Compatible with multiple finishing processes

Environmentally Friendly: Fully recyclable material

High Strength-to-Weight Ratio: Lightweight yet durable structural solution

Applications

Our galvanized steel products are used in a wide array of industries and structures:

Construction: roofing, wall cladding, framing systems, ceiling grids

Agriculture: fencing, storage structures, irrigation systems

HVAC Systems: ducting, ventilation structures, cable trays

Automotive and Transport: body parts, underbody panels, support frames

Energy & Infrastructure: solar panel frames, electric poles, transmission towers

Thanks to their versatility, galvanized components can be used in both indoor and outdoor projects with equal reliability.

Surface Finishing Options

We offer galvanized materials in the following finishes:

Spangled Surface

Skin-Pass Finish

Oiled or Dry Surface

Chromated or Non-Chromated Coating

Passivation Treatments

These options ensure that each product can meet technical and aesthetic specifications for demanding applications.

Packaging and Export

HL Metal provides export-ready solutions with professional packaging standards:

Waterproof wrapping for maritime shipping

Steel-strapped bundles with product labels

Custom barcoding and palletizing for logistics traceability

ISPM-15 certified wooden pallets for international delivery

We serve clients in over 20 countries and offer full customs documentation for seamless cross-border trade.

Why Choose HL Metal?

As a trusted supplier in the steel and metal industry, HL Metal is known for:

Fast lead times and reliable delivery

Flexible MOQ and custom production options

Compliance with EN and ASTM standards

Competitive pricing without sacrificing quality

Contact us today to get a detailed quote or request a product catalog tailored to your industry. Let us support your business with long-lasting galvanized steel solutions that deliver performance and protection.

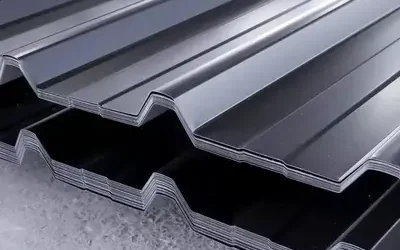

Steel Decking Sheet, Metal Decking Sheet, Composite Floor Decking Sheet

Steel Decking Sheet solutions offer superior structural support for concrete slabs and multi-story buildings. At HL Metal, we manufacture high-quality Metal Decking Sheet products designed for fast installation, high load-bearing capacity, and long-term durability.

Our range includes Composite Floor Decking Sheet options that bond seamlessly with concrete, forming a solid and reliable composite floor system. For projects that demand extra strength and corrosion resistance, we provide Concrete Floor Decking Sheet solutions available with galvanized coatings.

Each Under-Concrete Trapezoidal Sheet is engineered to reduce slab thickness, lower material costs, and accelerate construction schedules. These sheets are ideal for industrial buildings, warehouses, commercial centers, and parking structures.

Choose HL Metal for customized decking solutions tailored to your architectural and structural needs. All products comply with international standards and are export-ready for global delivery.

Technical Data Table

| Property | Value / Description |

|---|---|

| Profile Type | Trapezoidal, Open Below |

| Base Material | Galvanized Steel |

| Zinc Coating Thickness | Z140–Z275 |

| Sheet Thickness | 0.70 mm – 1.20 mm |

| Effective Width | 600 mm – 915 mm (depends on model) |

| Length Range | 3000 mm – 12000 mm |

| Profile Height | 50 mm – 75 mm |

| Applicable Standards | EN 10346, ASTM A653 |

| Application Areas | Concrete Floor Decking, Composite Slab Systems |