- Ana Sayfa

- Reinforcing Steel Mesh

Reinforcing Steel Mesh

Reinforcing Steel Mesh

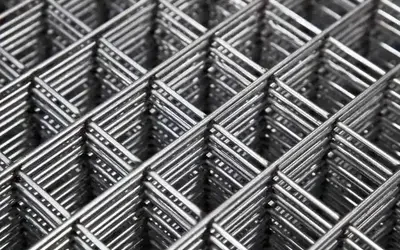

Reinforcing steel mesh, also known as welded wire mesh, is produced by drawing coiled ST I grade steel through a cold-drawing process to improve its physical properties. The material is then straightened and cut into desired lengths, resulting in high-strength, ribbed steel rods. These rods are then placed perpendicular to each other at specific intervals and joined together through spot welding, forming a durable steel mesh. There are three main types of reinforcing steel mesh:

Q-type mesh

R-type mesh

Custom-designed mesh based on project requirements

Q-Type Reinforcing Steel Mesh

Q-type steel mesh is widely used as reinforcement material in: slabs, shear walls, retaining walls, foundations, industrial floor concretes, tunnels and galleries, channels and drainage systems.

This type of mesh is manufactured by welding cold-drawn, ribbed, high-strength rods at fixed spacing, providing enhanced structural integrity and reducing labor time on site

| Mesh Dimensions | Mesh Aperture | Width | Length | Width | Steel Mesh | ||

| Width/Length | Width/Length | Width/Length | Protruding Wires | Protruding Wires | Weights | Kg/m2 | |

| (cm) | (mm) | (mm) | (mm) | (mm) | (kg) | ||

| Q106/106 | 500/215 | 150/150 | 4.5/4.5 | 100/100 | 25/175 | 17.62 | 1,66 |

| Q131/131 | 500/215 | 150/150 | 5.0/5.0 | 100/100 | 25/175 | 21.70 | 2,06 |

| Q158/158 | 500/215 | 150/150 | 5.5/5.5 | 100/100 | 25/175 | 26.36 | 2,49 |

| Q188/188 | 500/215 | 150/150 | 6.0/6.0 | 100/100 | 25/175 | 31.29 | 2,96 |

| Q221/221 | 500/215 | 150/150 | 6.5/6.5 | 100/100 | 25/175 | 36.65 | 3,47 |

| Q257/257 | 500/215 | 150/150 | 7.0/7.0 | 100/100 | 25/175 | 42.57 | 4,03 |

| Q257/188 | 500/215 | 150/150 | 7.0/6.0 | 100/100 | 25/175 | 36.89 | 3,49 |

| Q295/295 | 500/215 | 150/150 | 7.5/7.5 | 100/100 | 25/175 | 48.91 | 4,62 |

| Q295/257 | 500/215 | 150/150 | 7.5/7.0 | 100/100 | 25/175 | 45.72 | 4,33 |

| Q295/221 | 500/215 | 150/150 | 7.5/6.5 | 100/100 | 25/175 | 42.73 | 4,04 |

| Q295/188 | 500/215 | 150/150 | 7.5/6.0 | 100/100 | 25/175 | 40.04 | 3,79 |

| Q295/158 | 500/215 | 150/150 | 7.5/5.5 | 100/100 | 25/175 | 37.55 | 3,56 |

| Q317/317 | 500/215 | 150/150 | 7.8/7.8 | 100/100 | 25/175 | 52.86 | 5 |

| Q317/295 | 500/215 | 150/150 | 7.8/7.5 | 100/100 | 25/175 | 50.80 | 4,81 |

| Q317/257 | 500/215 | 150/150 | 7.8/7.0 | 100/100 | 25/175 | 47.61 | 4,52 |

| Q317/221 | 500/215 | 150/150 | 7.8/6.5 | 100/100 | 25/175 | 44.63 | 4,24 |

| Q317/188 | 500/215 | 150/150 | 8.0/6.0 | 100/100 | 25/175 | 42.00 | 3,98 |

| Q335/335 | 500/215 | 150/150 | 8.0/8.0 | 100/100 | 25/175 | 55.68 | 5,26 |

| Q335/317 | 500/215 | 150/150 | 8.0/7.8 | 100/100 | 25/175 | 54.18 | 5,13 |

| Q335/295 | 500/215 | 150/150 | 8.0/7.5 | 100/100 | 25/175 | 52.27 | 4,94 |

| Q335/257 | 500/215 | 150/150 | 8.0/7.0 | 100/100 | 25/175 | 49.08 | 4,64 |

| Q335/221 | 500/215 | 150/150 | 8.0/6.5 | 100/100 | 25/175 | 46.09 | 4,37 |

| Q335/188 | 500/215 | 150/150 | 8.0/6.0 | 100/100 | 25/175 | 43.40 | 4,11 |

| Q377/377 | 500/215 | 150/150 | 8.5/8.5 | 100/100 | 25/175 | 62.72 | 5,94 |

| Q377/335 | 500/215 | 150/150 | 8.5/8.0 | 100/100 | 25/175 | 59.17 | 5,6 |

| Q377/317 | 500/215 | 150/150 | 8.5/7.8 | 100/100 | 25/175 | 57.69 | 5,47 |

| Q377/295 | 500/215 | 150/150 | 8.5/7.5 | 100/100 | 25/175 | 55.77 | 5,28 |

| Q377/257 | 500/215 | 150/150 | 8.5/7.0 | 100/100 | 25/175 | 52.58 | 4,98 |

| Q377/221 | 500/215 | 150/150 | 8.5/6.5 | 100/100 | 25/175 | 49.60 | 4,71 |

| Q377/188 | 500/215 | 150/150 | 8.5/6.0 | 100/100 | 25/175 | 46.90 | 4,45 |

| Q424/424 | 500/215 | 150/150 | 9.0/9.0 | 100/100 | 25/175 | 70.33 | 6,66 |

| Q424/377 | 500/215 | 150/150 | 9.0/8.5 | 100/100 | 25/175 | 66.50 | 6,3 |

| Q424/335 | 500/215 | 150/150 | 9.0/8.0 | 100/100 | 25/175 | 62.96 | 5,96 |

| Q424/317 | 500/215 | 150/150 | 9.0/7.8 | 100/100 | 25/175 | 61.47 | 5,98 |

| Q424/295 | 500/215 | 150/150 | 9.0/7.5 | 100/100 | 25/175 | 59.55 | 5,64 |

| Q424/257 | 500/215 | 150/150 | 9.0/7.0 | 100/100 | 25/175 | 56.36 | 5,34 |

| Q424/221 | 500/215 | 150/150 | 9.0/6.5 | 100/100 | 25/175 | 53.38 | 5,07 |

| Q443/443 | 500/215 | 150/150 | 9.2/9.2 | 100/100 | 25/175 | 73.58 | 6,96 |

| Q443/377 | 500/215 | 150/150 | 9.2/8.5 | 100/100 | 25/175 | 67.97 | 6,45 |

| Q443/335 | 500/215 | 150/150 | 9.2/8.0 | 100/100 | 25/175 | 64.42 | 6,11 |

| Q443/317 | 500/215 | 150/150 | 9.2/7.8 | 100/100 | 25/175 | 62.94 | 5,98 |

| Q443/295 | 500/215 | 150/150 | 9.2/7.5 | 100/100 | 25/175 | 61.02 | 5,79 |

| Q443/257 | 500/215 | 150/150 | 9.2/7.0 | 100/100 | 25/175 | 57.83 | 5,49 |

| Q443/221 | 500/215 | 150/150 | 9.2/6.5 | 100/100 | 25/175 | 54.99 | 5,22 |

| Q473/473 | 500/215 | 150/150 | 9.5/9.5 | 100/100 | 25/175 | 78.37 | 7,42 |

| Q503/503 | 500/215 | 100/100 | 8.0/8.0 | 100/100 | 25/125 | 83.09 | 7,89 |

| Q513/513 | 500/215 | 100/100 | 8.1/8.1 | 100/100 | 25/125 | 85.20 | 8,09 |

| Q513/257 | 500/215 | 100/150 | 8.1/7.0 | 100/100 | 25/125 | 63.96 | 6,06 |

| Q524/524 | 500/215 | 150/150 | 10.0/10.0 | 100/100 | 25/175 | 86.97 | 8,22 |

| Q524/443 | 500/215 | 150/150 | 10.0/9.2 | 100/100 | 25/175 | 80.08 | 7,59 |

| Q524/424 | 500/215 | 150/150 | 10.0/9.0 | 100/100 | 25/175 | 78.60 | 7,44 |

| Q524/377 | 500/215 | 150/150 | 10.0/8.5 | 100/100 | 25/175 | 74.76 | 7,08 |

| Q524/335 | 500/215 | 150/150 | 10.0/8.0 | 100/100 | 25/175 | 71.21 | 6,74 |

| Q524/317 | 500/215 | 150/150 | 10.0/7.8 | 100/100 | 25/175 | 69.72 | 6,61 |

| Q524/295 | 500/215 | 150/150 | 10.0/7.5 | 100/100 | 25/175 | 67.81 | 6,42 |

| Q524/257 | 500/215 | 150/150 | 10.0/7.0 | 100/100 | 25/175 | 64.62 | 6,12 |

| Q589/589 | 500/215 | 150/150 | 10.6/10.6 | 100/100 | 25/175 | 97.53 | 9,24 |

| Q589/589 | 500/215 | 100/100 | 8.7/8.7 | 100/100 | 25/125 | 98,24 | 9,33 |

| Q589/503 | 500/215 | 100/100 | 8.7/8.0 | 100/100 | 25/125 | 90.65 | 8,61 |

| Q589/378 | 500/215 | 100/150 | 8.7/8.5 | 100/100 | 25/125 | 80.61 | 7,64 |

| Q589/335 | 500/215 | 100/150 | 8.7/8.0 | 100/100 | 25/125 | 76.96 | 7,3 |

| Q589/317 | 500/215 | 100/150 | 8.7/7.8 | 100/100 | 25/125 | 75.47 | 7,17 |

| Q589/295 | 500/215 | 100/150 | 8.7/7.5 | 100/100 | 25/125 | 73.66 | 6,98 |

| Q634/634 | 500/215 | 150/150 | 11.0/11.0 | 100/100 | 25/175 | 105.15 | 9,95 |

| Q636/636 | 500/215 | 100/100 | 9.0/9.0 | 100/100 | 25/125 | 104.96 | 9,99 |

| Q636/424 | 500/215 | 100/150 | 9.0/9.0 | 100/100 | 25/125 | 87.80 | 8,32 |

| Q709/424 | 500/215 | 100/150 | 9.5/9.0 | 100/100 | 25/125 | 93.78 | 8,89 |

| Q754/754 | 500/215 | 150/150 | 12.0/12.0 | 100/100 | 25/175 | 125.16 | 11,84 |

| Q785/785 | 500/215 | 100/100 | 10.0/10.0 | 100/100 | 25/125 | 129.79 | 12,33 |

| Q785/295 | 500/215 | 100/150 | 10.0/7.5 | 100/100 | 25/125 | 89.40 | 8,48 |

| Q785/257 | 500/215 | 100/150 | 10.0/7.0 | 100/100 | 25/125 | 86.21 | 8,18 |

| Q950/950 | 500/215 | 100/100 | 11.0/11.0 | 100/100 | 25/125 | 156.92 | 14,92 |

| Q1131/1131 | 500/215 | 100/100 | 12.0/12.0 | 100/100 | 25/125 | 186.78 | 17,76 |

R-Type Reinforcing Steel Mesh

For thicker mesh types, edge reductions are not applied by default. Upon request, edge trimming can be implemented to minimize material loss along the mesh perimeter.

| Mesh Dimensions | Mesh Spacing | Wire Diameter | Length | Width | Steel Mesh | ||

| Width/Length | Width/Length | Width/Length | Protruding Wires | Protruding Wires | Weights | Kg/m2 | |

| (cm) | (mm) | (mm) | (mm) | (mm) | (kg) | ||

| R 106 | 500/215 | 150/250 | 4.5 / 4.5 | 125/125 | 25/175 | 14,12 | 1,33 |

| R 131 | 500/215 | 150/250 | 5.0 / 5.0 | 125/125 | 25/175 | 17.40 | 1,64 |

| R 158 | 500/215 | 150/250 | 5.5 / 5.0 | 125/125 | 25/175 | 19.71 | 1,86 |

| R 188 | 500/215 | 150/250 | 6.0 / 5.0 | 125/125 | 25/175 | 22.16 | 2,1 |

| R 221 | 500/215 | 150/250 | 6.5 / 5.0 | 125/125 | 25/175 | 24.82 | 2,35 |

| R 257 | 500/215 | 150/250 | 7.0 / 5.0 | 125/125 | 25/175 | 27.76 | 2,63 |

| R 295 | 500/215 | 150/250 | 7.5 5.0 | 125/125 | 25/175 | 30.91 | 2,93 |

| R 317 | 500/215 | 150/250 | 7.8 / 5.0 | 125/125 | 25/175 | 32.87 | 3,12 |

| R 335 | 500/215 | 150/250 | 8.0 / 5.0 | 125/125 | 25/175 | 34.27 | 3,25 |

| R 377 | 500/215 | 150/250 | 8.5 / 5.5 | 125/125 | 25/175 | 39.19 | 3,72 |

| R 390 | 500/215 | 150/250 | 8.7 5.5 | 125/125 | 25/175 | 40.66 | 3,86 |

| R 424 | 500/215 | 150/250 | 9.0 / 5.5 | 125/125 | 25/175 | 42.97 | 4,08 |

| R 443 | 500/215 | 150/250 | 9.2 5.5 | 125/125 | 25/175 | 44.58 | 4,22 |

| R 473 | 500/215 | 150/250 | 9.5 / 5.5 | 125/125 | 25/175 | 46.96 | 4,46 |

| R 503 | 500/215 | 100/250 | 8.0 / 6.0 | 125/125 | 25/125 | 51.02 | 4,83 |

| R 513 | 500/215 | 100/250 | 8.1 6.0 | 125/125 | 25/125 | 52.07 | 4,93 |

| R 524 | 500/215 | 150/250 | 10.0 / 6.0 | 125/125 | 25/175 | 52,74 | 4,99 |

| R 567 | 500/215 | 100/250 | 8.5 / 6.0 | 125/125 | 25/125 | 56.27 | 5,34 |

| R 577 | 500/215 | 100/250 | 8.6 / 6.5 | 125/125 | 25/125 | 59,06 | 5,45 |

| R 577 | 500/215 | 150/250 | 10.5 / 6.5 | 125/125 | 25/175 | 58,78 | 5,57 |

| R 589 | 500/215 | 100/250 | 8.7 / 6.5 | 125/125 | 25/125 | 60.22 | 5,71 |

| R 589 | 500/215 | 150/250 | 10.6 / 6.5 | 125/125 | 25/175 | 59,69 | 5,66 |

| R 634 | 500/215 | 150/250 | 11.0 6.5 | 125/125 | 25/175 | 63,40 | 6,02 |

| R 636 | 500/215 | 100/250 | 9.0 / 6.5 | 125/125 | 25/125 | 63.57 | 6,04 |

| R 709 | 500/215 | 100/250 | 9.5 / 6.5 | 125/125 | 25/125 | 69.56 | 6,61 |

| R 785 | 500/215 | 100/250 | 10.0 6.5 | 125/125 | 25/125 | 75.97 | 7,21 |

| R 866 | 500/215 | 100/250 | 10.5/7.0 | 125/125 | 25/125 | 84.39 | 8,01 |

Custom Reinforcing Steel Meshes

Custom Reinforcing Steel Meshes are manufactured in any cross-section as cm²/m, with a maximum length bar of 12 meters and a maximum width bar of 3.20 meters. The maximum bar diameter is 12 mm, and the minimum bar diameter is 3 mm. Mesh spacing is produced in increments of 50 mm, 75 mm, 100 mm, and their multiples.

Steel meshes used in tunnel formwork systems, such as mine mesh, wall mesh, and support mesh, are considered custom steel meshes.

Custom Reinforcing Steel Meshes are produced according to project specifications or customer requirements.

Reinforcing steel mesh, steel reinforcement mesh, concrete reinforcing mesh, welded steel mesh, construction reinforcement mesh, structural steel mesh, HL Metal Demir Çelik reinforcing mesh, durable steel mesh, industrial steel reinforcement, and export-quality reinforcing mesh are essential components in the modern construction industry. These materials play a critical role in providing strength, stability, and durability to concrete structures, ensuring long-lasting performance under various loads and conditions.

At HL Metal Demir Çelik Sanayi, we specialize in supplying high-quality reinforcing steel mesh tailored to meet the demands of industrial, commercial, and infrastructure projects. Our steel reinforcement mesh and welded steel mesh products are manufactured using precision techniques, ensuring consistent mesh apertures, accurate dimensions, and superior tensile strength. Whether for small-scale residential projects or large-scale industrial and highway works, our durable steel mesh solutions are designed to perform reliably.

Concrete reinforcing mesh from HL Metal is used in foundations, floors, walls, pavements, and precast concrete elements, providing excellent crack control and load distribution. Our structural steel mesh meets international standards, making it suitable for export-quality reinforcing mesh applications across global markets.

HL Metal’s construction reinforcement mesh is available in various wire diameters, mesh sizes, and panel dimensions, ensuring flexibility and adaptability for project-specific needs. With a strong focus on quality control and technical support, HL Metal Demir Çelik reinforcing mesh products help customers achieve superior construction outcomes.

By choosing HL Metal’s industrial steel reinforcement solutions, clients gain access to proven expertise, durable materials, and export-ready products trusted by professionals worldwide. Whether you need standard panels or custom-made mesh, HL Metal delivers steel reinforcement mesh solutions that enhance the safety, durability, and performance of every construction project.

Reinforcing Steel Mesh — Advanced Reinforcement for Durable Concrete Structures

Executive summary and product overview

Reinforcing Steel Mesh is an engineered solution that enhances concrete tensile performance and controls crack propagation across slabs, walls and foundations. Also commonly referred to as Steel Reinforcement Mesh, Reinforcement Mesh or Rebar Mesh, this product is widely adopted across residential, commercial and heavy civil projects due to its repeatable quality, predictable performance and rapid site installation. Whether you are sourcing Welded Steel Mesh for Reinforcement in panel form (Welded Reinforcing Mesh Panels) or specifying bespoke configurations as Custom Size Reinforcing Steel Mesh, mesh reinforcement provides a pragmatic alternative to individually tied rebar in many applications.

This technical and commercial guide outlines the principal types — including Square Reinforcing Mesh and Rectangular Reinforcing Mesh — production methods such as Hot Rolled Reinforcement Mesh and Cold Drawn Reinforcing Mesh, performance characteristics for High Strength Reinforcing Mesh and Durability options like Corrosion Resistant Reinforcement Mesh, practical selection criteria for Reinforcing Mesh for Concrete Slabs and Reinforcing Mesh for Foundations, and procurement guidance for working with a Reinforcing Steel Mesh Supplier or Reinforcing Mesh Manufacturer.

Product types, manufacturing and material science

Welded vs. alternate construction

Welded Steel Mesh for Reinforcement is manufactured by intersecting longitudinal and transverse wires and spot-welding at junctions. Welded Reinforcing Mesh Panels are commonly supplied in standardized dimensions but can be fabricated to project-specific sizes. In contrast, other reinforcement systems use individually placed rebar or woven systems. Welded mesh provides uniform spacing and consistent mechanical behavior which is ideal for repeatable applications such as Reinforcing Steel Mesh for Flooring or Steel Mesh for Road Construction.

Wire metallurgy and process

Production methods influence mechanical properties. Hot Rolled Reinforcement Mesh provides ductility and toughness suitable for heavy-duty applications (often categorized as Heavy Duty Reinforcing Mesh). Cold Drawn Reinforcing Mesh typically yields higher yield strengths and better dimensional tolerances. Material selection should reference project specifications and local codes when choosing between Hot Rolled Reinforcement Mesh or Cold Drawn Reinforcing Mesh.

Geometries and sizes

Standard Size Reinforcing Mesh is available in common grid patterns — for example 50 mm x 50 mm or 100 mm x 100 mm — but many projects demand Custom Size Reinforcing Steel Mesh to account for architectural constraints, embeds or irregular slab perimeters. Square Reinforcing Mesh offers symmetric structural response while Rectangular Reinforcing Mesh can be used where directional stiffness is required.

Key applications and domain-specific recommendations

Reinforcement Mesh is specified across a broad portfolio of structural work. Typical uses include:

- Reinforcing Mesh for Concrete Slabs: industrial floors, warehouse decks and domestic ground slabs where uniform crack control is required.

- Reinforcing Mesh for Foundations: raft foundations and slab-on-grade where distribution of tensile stresses improves serviceability.

- Reinforcement Mesh for Walls: thin reinforced walls, precast panels and retaining structures.

- Reinforcing Steel Mesh for Flooring: overlays, toppings and suspended slab systems.

- Steel Mesh for Road Construction: pavement repairs, overlays and structural asphalt or concrete layers requiring crack suppression.

- Reinforcing Mesh for Tunnels and Bridges: specialized grades (High Strength Reinforcing Mesh and Corrosion Resistant Reinforcement Mesh) for demanding infrastructure applications.

For each application, coordinate with our Engineering Services for load-based selection, cover requirements and detailing.

Performance attributes and specification drivers

Strength & serviceability

High Strength Reinforcing Mesh improves ultimate capacity, while carefully selected mesh spacing and wire diameter mitigate serviceability problems such as deflection and cracking. Long-lasting Reinforcement Mesh designs focus not only on initial capacity but on sustained performance under environmental exposure and cyclic loading.

Durability & corrosion protection

Corrosion Resistant Reinforcement Mesh is available via galvanizing, epoxy coating or stainless-steel wire to address chloride exposure, coastal atmospheres or chemically aggressive soils. Durable Reinforcing Steel Mesh products reduce life-cycle costs and maintenance interventions.

Constructability

Welded Reinforcing Mesh Panels accelerate installation, reduce labor hours and minimize on-site tying. For large-volume orders, Wholesale Reinforcing Steel Mesh procurement and working with a reputable Reinforcing Mesh Stockist can reduce lead times and unit costs.

Procurement: how to engage suppliers and compare offers

When sourcing reinforcement, evaluate potential partners on technical capability, quality control, certification and logistics. Ask prospective vendors for the following:

- Batch test certificates and tensile properties for the proposed Rebar Mesh or Welded Steel Mesh for Reinforcement.

- Dimensional plans for Welded Reinforcing Mesh Panels and confirmation of Standard Size Reinforcing Mesh availability.

- Options for Custom Size Reinforcing Steel Mesh and associated lead times.

- Evidence of corrosion protection treatments where Corrosion Resistant Reinforcement Mesh is specified.

Typical supplier roles include Reinforcing Steel Mesh Supplier, Reinforcing Mesh Manufacturer and, for international projects, Reinforcement Mesh Exporter. For e-commerce buyers, choose licensed channels to Buy Reinforcement Mesh Online and verify freight terms before accepting quotes. If your project is bulk-oriented, contact our wholesale desk for competitive Wholesale Reinforcing Steel Mesh pricing and logistics.

Installation best practices

Positioning and cover

Correct positioning is critical. Reinforcing Mesh for Concrete Slabs must be supported to maintain the specified concrete cover; incorrect cover reduces durability and compromises performance. Overlap (lap length) recommendations should follow project-specific engineering guidance — for Welded Reinforcing Mesh Panels, lap details differ from rebar lap schedules.

Cutting, bending and field modifications

Cutting or re-shaping mesh in the field must be executed with suitable tools and by trained personnel. Cold Drawn Reinforcing Mesh and Hot Rolled Reinforcement Mesh respond differently to bending; over-manipulation of higher-strength wire may create brittle zones and should be avoided without engineering consent.

Coordination with other trades

Ensure coordination with electrical and plumbing trades to avoid penetrations through reinforcement that can create stress concentrations. Preplanning reduces rework and maintains the integrity of the Reinforced Steel Mesh in the finished slab or wall.

Comparative analysis: Rebar Mesh vs. conventional bar reinforcement

Rebar Mesh (prefabricated grid) is often faster to install than individually tied bars and provides consistent spacing which enhances repeatable slab behavior. Conventional rebar remains preferable for heavily reinforced beams, complex anchorage zones or where bar sizes and spacing vary considerably. Selection should be performed by the structural engineer with reference to the design’s load path and detailing requirements.

Commercial considerations: pricing, stock and logistics

Reinforcing Steel Mesh Price is influenced by raw material costs, wire diameter, coating type (e.g., galvanized or epoxy), panel size and processing method. Reinforcing Mesh Stockist networks and established Reinforcing Mesh Manufacturers can often supply immediate stock for urgent projects; for bespoke Custom Size Reinforcing Steel Mesh allow additional lead time. If you prefer to Buy Reinforcement Mesh Online, use certified portals and confirm shipping and handling for heavy panels.

Case studies and sector examples

Industrial flooring

In heavy-duty warehousing, Heavy Duty Reinforcing Mesh and High Strength Reinforcing Mesh have been used to achieve long-lasting, low-maintenance floors able to withstand forklift loads and concentrated pallet loads.

Bridge deck rehabilitation

For repair overlays, Corrosion Resistant Reinforcement Mesh embedded in high-performance concrete extends service life and mitigates chloride ingress on bridge decks.

Urban road resurfacing

Steel Mesh for Road Construction is frequently installed as a reinforcement layer prior to concrete resurfacing to limit reflective cracking and to improve load transfer.

Frequently asked questions (FAQ)

What is the typical lead time for Standard Size Reinforcing Mesh?

Lead times depend on stock levels and manufacturing schedules. Standard Size Reinforcing Mesh may be available from stock, while Custom Size Reinforcing Steel Mesh requires fabrication time; consult a Reinforcing Steel Mesh Supplier for firm delivery dates.

Can I use weld-mesh instead of traditional rebar for a foundation?

In many cases, yes — Reinforcing Mesh for Foundations is a viable solution for shallow foundations and mat slabs, but structural drawings must confirm the adequacy of mesh in lieu of discrete bars, particularly for load-bearing or embed-heavy designs.

Which mesh is best for coastal projects?

For coastal exposure choose Corrosion Resistant Reinforcement Mesh with appropriate coating or stainless steel wire to prevent premature deterioration.

Related products and internal resources

- Rebar & Bar Reinforcement

- Welded Reinforcing Mesh Panels

- Structural Design & Detailing

- Technical Blog: Reinforcement Guides