Metal Weight Calculator Overview

The Metal Weight Calculator—also known as the Steel Weight Calculator—is a mission-critical tool for engineers, buyers, fabricators, and construction professionals. It delivers fast, reliable estimates for part weight, weight per meter, and total shipment weight across a broad portfolio: sheet, plate, pipe, tube, round bar, square/flat bar, angles, channels, and I/H beams. Beyond convenience, accurate weight forecasting streamlines logistics planning, optimizes transport costs, and tightens pricing models.

Online Metal Weight Calculator, Custom Metal Weight Calculator, Steel Weight Chart, Metal Weight Chart, Steel Density and Weight Calculation, and Calculate Steel Weight Online. Whether you’re specifying materials, preparing a quotation, or validating a production plan, the guidance below helps you calculate weights accurately and consistently—while pointing you to allied services, such as CNC Laser Cutting, CNC Plasma Cutting, Guillotine Shearing, and Press Brake Bending.

How to Use the Metal Weight Calculator

1) Select the Product Geometry

Start by choosing the geometry that matches your part: sheet/plate, pipe/tube, hollow sections, bars, or profiles/beams. Because each geometry has a distinct cross-sectional formula, selecting the correct type is essential for accuracy.

2) Enter Dimensions Carefully

Input thickness, width, height, outside diameter (OD), inside diameter (ID), wall thickness (WT), and length (L) using consistent units. We recommend millimeters (mm) for entry and converting to meters (m) before volume calculations. Visit the Formulas & Conversions section for the exact expressions.

3) Choose the Correct Material Density

For carbon steel, a density of 7,850 kg/m³ is commonly used. Stainless steel typically ranges from 7,900 to 8,100 kg/m³. Surface treatments (e.g., galvanizing) add marginal weight that may matter in critical scenarios. If you are specifically working on zinc-coated products, consult

Galvanized Steel Sheets.

4) Validate, Document, and Share

Production tolerances, weld seams, edge radii, coatings, moisture, and packaging can shift the final weight. For mission-critical jobs or tight logistics windows, validate the theoretical output against actual weighbridge data or supplier certificates. Store your calculation history for auditability during RFQs and quality reviews.

Product-Based Metal Weight Calculations

Sheet & Plate

For sheet and plate, volume is the product of thickness × width × length (all in meters). Multiply the volume by the material density to obtain mass in kilograms. The approach is straightforward and efficient for cut to length workflows where coil-to-sheet processing is common—see Cut to Length from Coil and Slitting for precision coil processing that minimizes scrap and handling costs.

Worked Example (Sheet / Plate)

A 10 mm × 1,500 mm × 3,000 mm (0.01 m × 1.5 m × 3 m) S235JR plate has a volume of 0.01 × 1.5 × 3 = 0.045 m³. Multiplying by 7,850 kg/m³ yields a mass of 353.25 kg (approx.). Increase the density slightly for certain stainless grades or adjust for coatings where necessary.

Operational Tip

For thicknesses above ~12 mm, CNC Plasma Cutting is often a cost-effective choice; for ≤12 mm with tight tolerances or intricate shapes, consider CNC Laser Cutting. Proper upstream selection reduces rework and preserves edge quality.

Pipe & Tube Metal Weight Calculator (CHS)

For circular hollow sections, the cross-sectional area is (π/4) × (OD² − ID²), where ID = OD − 2 × WT if wall thickness is known. Volume is area × length, and mass is volume × density. This method suits carbon steel pipe and tube, as well as stainless and galvanized variants.

Worked Example (Pipe)

OD 60.3 mm, WT 3.2 mm, L 6,000 mm ⇒ ID = 60.3 − 2×3.2 = 53.9 mm. Convert to meters before applying the formula, then multiply by 7,850 kg/m³ to obtain mass. Remember to account for end prep (bevels), weld seams, and cutting tolerances in fabrication quotes.

Related Product Pages

Explore Steel Pipe and Galvanized Pipe for corrosion resistance and service life extensions in outdoor or marine environments.

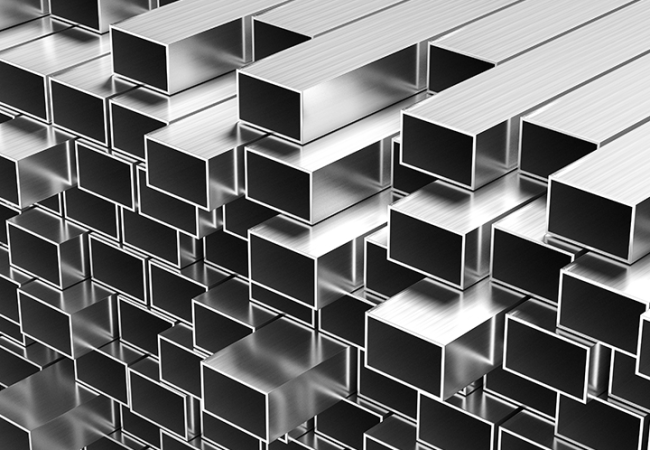

Hollow Sections Metal Weight Calculator (SHS / RHS / CHS)

For square (SHS) and rectangular (RHS) hollow sections, determine the gross outer area and subtract the inner void based on wall thickness. As with CHS, keep corner radii in mind—rounded corners slightly reduce cross-sectional area compared to perfectly sharp corners, but the impact is typically modest for theoretical estimates.

Worked Example (SHS)

100 × 100 × 5 mm, L = 6 m: Outer area = 0.1 × 0.1 = 0.01 m²;

inner side = 100 − 2×5 = 90 mm ⇒ inner area = 0.09 × 0.09 = 0.0081 m².

Cross-sectional area = 0.01 − 0.0081 = 0.0019 m². Volume = 0.0019 × 6 = 0.0114 m³.

Mass = 0.0114 × 7,850 ≈ 89.5 kg.

Browse the Range

See Hollow Sections (SHS/RHS/CHS) for size availability, tolerances, and material grades. For customized orders, contact our team.

Round / Square / Flat Bars

Round Bar (Cylindrical)

Area = (π/4) × d². Multiply by length and density to obtain mass. For machining jobs, embed an allowance for material removal, fixtures, and finishing steps.

Square & Flat Bar Metal Weight Calculator

For square bar, area = a × a. For flat bar (strip), area = thickness × width. Longitudinal join tolerances and edge conditions are minor but may matter in ultra-precise metrology applications.

Complementary Services

Explore Machining Services for turning, milling, and drilling, and Sandblasting & Painting for protective finishes.

Angles (L), Channels (U/C), I/H Beams

Angle Bar Metal Weight Calculator, For structural sections, manufacturers often publish reliable kg/m values by series. While you can theoretically compute the area by summing web and flange elements (minus fillets and radii), standardized tables provide faster, widely accepted benchmarks for design and procurement.

Angles (L)

Equal or unequal leg options are common. Approximate with two flat strips and refine as necessary.

Channels (U/C)

Represent the sum of two flanges plus web thicknesses. Series such as UPE and UPN follow different geometry rules; referencing tables speeds up comparison.

I/H Beams

Choose from IPE, IPN, HEA, HEB, HEM depending on load criteria and architectural considerations. When in doubt, cross-check kg/m reference values and consult engineering guidelines for span and deflection.

Explore Structural Steel

See Angle Steel, Channel Steel, and H/I Beams for dimensional ranges and availability.

Core Formulas, Densities & Unit Conversions

Primary Relationship (H4)

Mass (kg) = Volume (m³) × Density (kg/m³)

Cross-Sectional Area Formulas (H4)

Sheet / Plate

Area = thickness × width (m²); Volume = area × length (m).

Pipe / CHS

Area = (π/4) × (OD² − ID²), with ID = OD − 2 × wall thickness (WT).

SHS / RHS

Area = (Bo × Ho) − (Bi × Hi).

Round Bar

Area = (π/4) × d².

Typical Densities (H4)

- Carbon Steel: 7,850 kg/m³

- Stainless Steel: 7,900–8,100 kg/m³ (grade-dependent)

- Galvanized Steel: base steel + zinc coating (small net increase)

- Aluminum (for comparison): ~2,700 kg/m³

Unit Conversions (H4)

- mm → m: divide by 1,000.

- cm → m: divide by 100.

- kg → ton: 1,000 kg = 1 ton.

- kg/m → total mass: multiply by total length (m).

Tolerances, Coatings & Packaging

Manufacturing tolerances (thickness, WT, ovality), corner radii, weld seams, coatings, humidity, and packaging can influence total shipment weight. For critical loads, request EN 10204 (3.1) certificates, weighbridge data, or pre-shipment inspection records.

Reference Weight Charts (Examples)

I/H Beams (kg/m) – Example Values

| Series | Example Size | Approx. kg/m | Note |

|---|---|---|---|

| HEA | HEA 200 | ≈ 61.3 | Manufacturer tolerances apply |

| HEB | HEB 200 | ≈ 79.2 | Series-specific geometries |

| HEM | HEM 200 | ≈ 101.0 | Heavier section; plan lifting |

| IPE | IPE 200 | ≈ 26.2 | Check span and deflection |

SHS (Square Hollow Section) – Example kg/m

| Size (mm) | Wall (mm) | Approx. kg/m | Note |

|---|---|---|---|

| 50 × 50 | 3.0 | ≈ 4.4 | Density 7.85 used |

| 80 × 80 | 4.0 | ≈ 9.2 | Manufacturer tolerances |

| 100 × 100 | 5.0 | ≈ 14.9 | Corner radii impact area |

How to Use These Charts

These values are reference-only and ideal for quick estimates during design or procurement. Always verify final weights with supplier datasheets or actual measurements prior to shipment, especially when crane capacity, road tonnage limits, or container payloads are at stake.

Applications, Workflows & Practical Tips

Construction & Site Operations

For beams, columns, and floor systems, balancing section weight with structural performance is key. The calculator speeds up feasibility checks and helps align transport, lifting equipment, and site storage. When scheduling deliveries, coordinate with crane availability and ensure ground bearing pressures are observed. For inventory rotation, tag bundles with calculated weights and serials for traceability.

Industrial Production & Fabrication

In high-mix, low-volume fabrication, fast and consistent weight estimates compress quote lead times. Integrating the calculator in ERP/CRM reduces manual entry and error risk. Combining cut to length and slitting lowers scrap, standardizes inputs, and stabilizes takt times. For heavy plate fabrication, plan plasma or laser operations in conjunction with press brake availability to avoid bottlenecks.

Workshops, Prototyping & Engineering

For prototypes, apply a contingency factor (e.g., 2–5%) to cover unknowns in tolerances and finishing. Use the calculator to align purchasing with machining time estimates. If weight is a design driver, compare material classes (e.g., stainless vs. carbon steel vs. aluminum) to determine lifecycle cost implications.

Surface Protection & Finishing

Galvanizing and industrial coatings deliver corrosion resistance in marine and high-humidity environments. Browse Galvanized Steel Sheets and Sandblasting & Painting. Account for coating thickness in mass-critical applications (e.g., aerial platforms, elevator retrofits).

Logistics, Packaging & Compliance

Bundle weights and center-of-gravity tags improve handling safety. For containerized shipments, check payload ceilings and distribute mass evenly. Use proper dunnage, strapping, and moisture protection to prevent damage and condensation. For the EU market, ensure documentation aligns with EN standards and labeling rules.

Related Pages (Internal Links)

FAQ – Frequently Asked Questions

Are calculator results exact or theoretical?

Short Answer

They are theoretical baselines. Real-world values vary due to tolerances, coatings, humidity, and packaging.

More Detail

For critical lifts or cross-border logistics, confirm with supplier datasheets, certificates, or scale readings.

Which density value should I select?

Short Answer

Carbon steel: 7,850 kg/m³; stainless: 7,900–8,100 kg/m³ depending on grade.

More Detail

If you have an EN 10204 3.1 certificate, use the declared density and tolerances for maximum accuracy.

When should I use charts versus formulas?

Short Answer

Charts are fast for standard sections; formulas are ideal for custom dimensions and engineering trade-offs.

More Detail

In practice, many teams cross-check both for robust pricing and design assurance.

Can we tailor the calculator for our workflow?

Short Answer

Yes. You can customize presets, unit systems, and outputs to integrate with ERP/CRM or quoting tools.

More Detail

Ask our team about API endpoints and data export options—see Contact.

Does galvanizing significantly change weight?

Short Answer

It adds weight but typically not enough to affect most transport plans—unless you are operating near payload limits.

More Detail

For weight-sensitive applications (e.g., lifts, platforms), include coating thickness in your mass budget.

What are common pitfalls in weight estimation?

Short Answer

Unit mistakes, ignoring tolerances, neglecting weld/seam additions, and overlooking packaging/pallet weights.

More Detail

Build a checklist: units, geometry, density, allowances, compliance documents. For exports, align INCO terms and documentation early.

Conclusion & Call-to-Action

This advanced guide to the Metal Weight Calculator equips you with the formulas, workflows, and best practices to estimate material mass at speed—across sheets, plates, pipes, tubes, hollow sections, bars, angles, channels, and I/H beams. Use it to de-risk logistics, optimize procurement, and accelerate quoting cycles.

Take the Next Step

- Request a Quote – share your dimensions and material grade for a fast, precise offer.

- Explore services: CNC Laser Cutting,

CNC Plasma Cutting,

Press Brake Bending,

Guillotine Shearing. - Browse products: Hollow Sections,

Steel Beams,

Galvanized Sheets,

Steel Pipe,

Stainless Steel.